LiFePO4 Batteries: A Guide to the Best Brands and Models

Discover top LiFePO4 battery brands and models for lasting power. Featured brands include Redway, SOK, Li Time, and Battleborn, offering reliable energy storage for electric cars and solar setups. Learn about different types, pros and cons, and factors to consider when selecting the right LiFePO4 battery for your needs.

What are LiFePO4 Batteries?

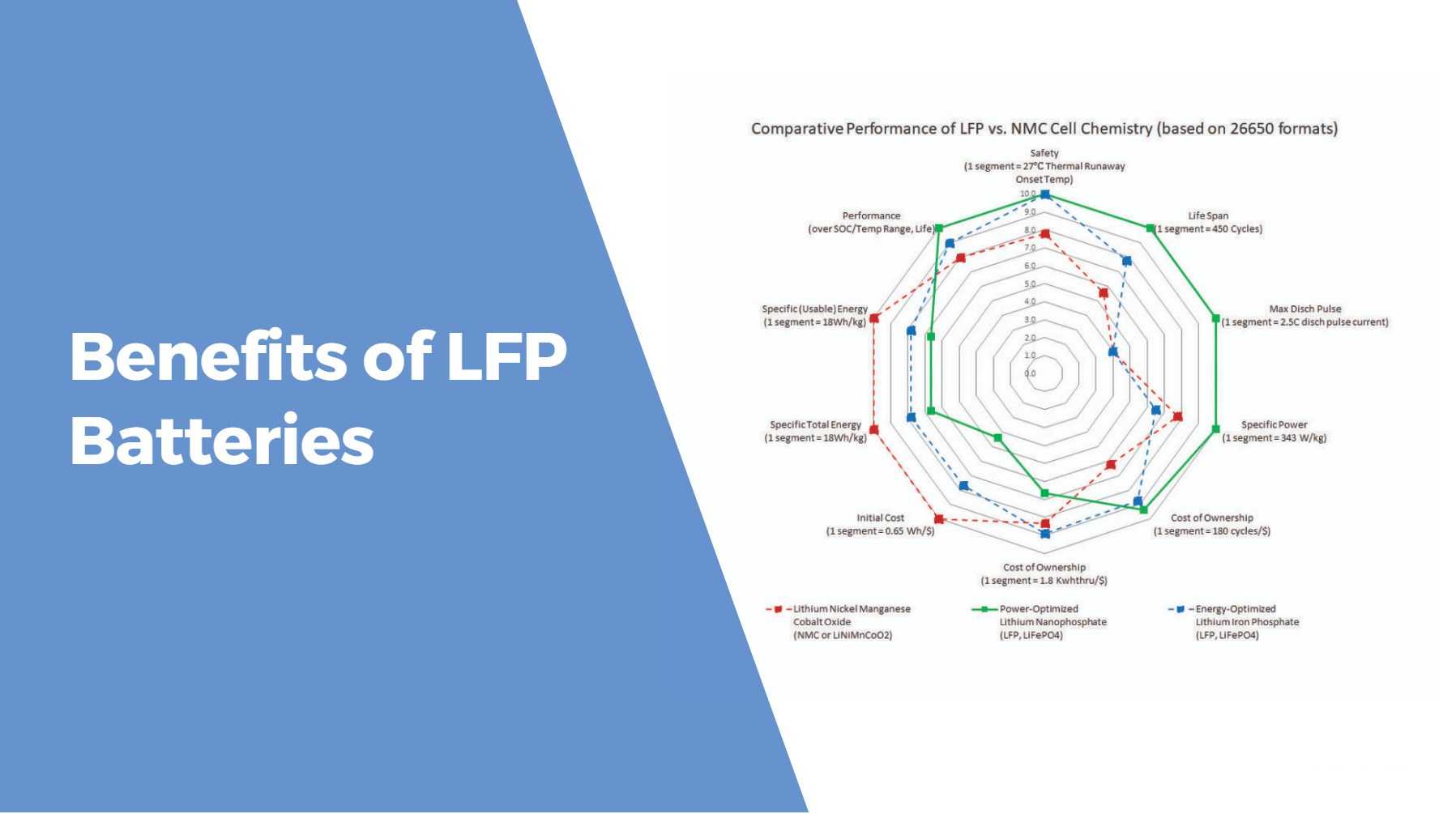

LiFePO4 batteries, or Lithium Iron Phosphate batteries, are advanced rechargeable batteries known for their longevity, safety, and energy efficiency. They utilize iron phosphate as a cathode material, which offers enhanced stability and reduces the risk of thermal runaway, making them safer than other lithium-ion battery chemistries. LiFePO4 batteries are widely used in various applications, including electric vehicles, solar energy storage systems, and portable electronics, due to their high energy density and long cycle life.

These batteries are compact, handle many charge cycles, and don’t overheat or catch fire easily. Great for electric cars and home energy storage due to their reliability.

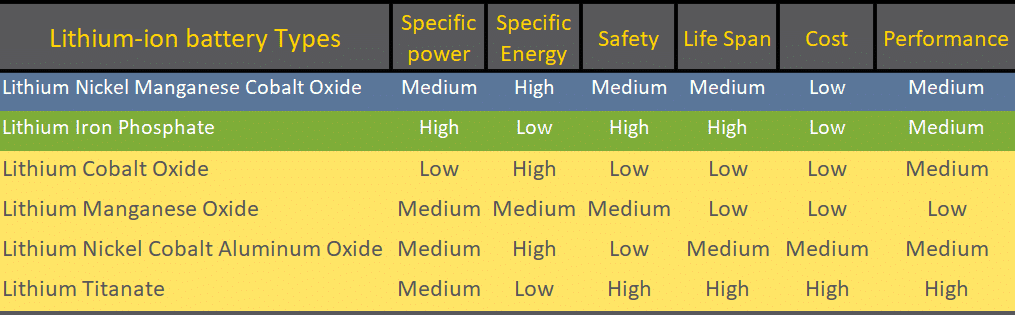

The Different Types of LiFePO4 Batteries

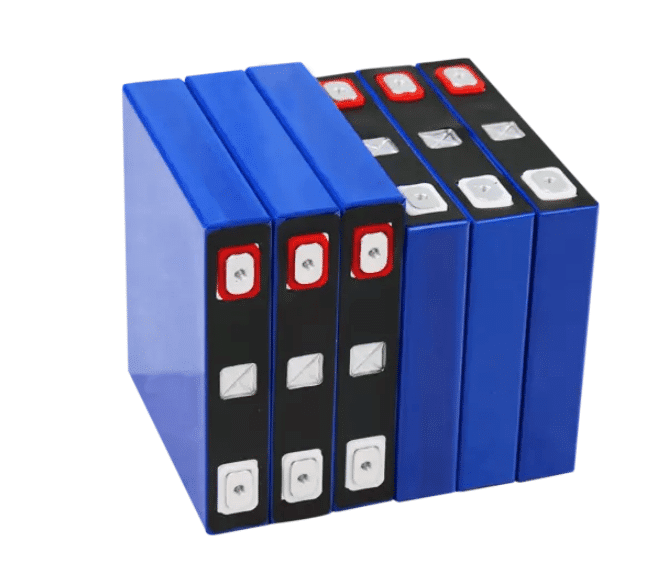

Different types of LiFePO4 batteries include cylindrical, prismatic, pouch, and large-format cells. Cylindrical cells, like AA batteries, offer more cycles but are heavier due to steel shells. Prismatic cells, ideal for electric vehicles, are lighter with square shapes. Pouch batteries are flexible, fitting smartphones, while large-format cells provide backup power for data centers.

Cylindrical ones, like AA batteries, are common in gadgets. The cylindrical type typically offers slightly more cycles compared to the prismatic LiFePO4 cell. Cylindrical cells tend to be heavier due to their steel shells, whereas prismatic cells are lighter as they often utilize stainless steel and aluminum shells.

Prismatic ones, with a rectangular shape, are great for electric vehicles. The square-shaped prismatic design enables a close arrangement of cells, whereas the cylindrical type inherently results in gaps. Cylindrical cells usually carry more weight due to their reliance on steel shells, while prismatic cells are lighter thanks to their usage of stainless steel and aluminum shells. Cylindrical cells, with their established history and simpler production, are cheaper to manufacture. Prismatic cells, being newer and constrained by technology and lacking standardized specifications, typically have higher manufacturing costs.

Pouch batteries, thin and flexible, fit well in devices like smartphones.

Large-format ones provide long-term backup power for places like data centers. Choosing the right type depends on your needs and where you’ll use it.

Pros and Cons of LiFePO4 Batteries

The pros of LiFePO4 batteries include a long lifespan, up to 10 times more charge cycles, and enhanced safety compared to traditional lithium-ion batteries. However, they are bulkier due to lower energy density and may have higher initial costs. Despite drawbacks, their advantages make them a promising option for sustainable power solutions.

Pros:

- Long Lifespan: LiFePO4 batteries last much longer than other types, offering up to 10 times more charge cycles, leading to significant cost savings over time.

- Safety: They are safer than traditional lithium-ion batteries, with reduced risk of fires or explosions. The stable voltage throughout discharge ensures consistent performance.

Cons:

- Bulkier Size: LiFePO4 cells are larger due to lower energy density, which may limit their suitability in space-constrained situations.

- Initial Cost: While prices are decreasing, initial costs can still be higher compared to alternatives like traditional lead-acid batteries.

Despite some drawbacks, the overall advantages make LiFePO4 batteries an attractive option for industries seeking sustainable power solutions in the future.

What are the Best Brands LiFePO4 Batteries in 2024?

Best LiFePO4 battery brands in 2024 include Battle Born Batteries, known for quality and built-in Battery Management System (BMS); Renogy, offering efficient solar panels and durable batteries for RVs and boats; and Redway Battery, providing budget-friendly options with advanced safety features. Consider factors like capacity and cycle life when choosing the best brand for your needs.

Several top brands in the LiFePO4 battery market are known for their quality and unique features:

- Battle Born Batteries: Renowned for high quality and longevity, equipped with built-in Battery Management System (BMS).

- Renogy: Recognized for efficient solar panels and durable LiFePO4 batteries, catering to RVs, boats, and homes.

- Redway Battery: Offers budget-friendly LiFePO4 batteries with advanced safety features like overvoltage and short-circuit protection.

- Victron Energy: Notable for reliable LiFePO4 batteries with a focus on performance and efficiency.

- SimpliPhi Power: Known for advanced energy storage solutions, including LiFePO4 batteries.

- RELiON Battery: A reputable brand offering high-performance LiFePO4 batteries for various applications.

- ExpertPower: Offers budget-friendly LiFePO4 batteries with advanced safety features like overvoltage and short-circuit protection.

Consider factors such as capacity, voltage rating, cycle life expectancy, and specific application requirements when choosing the best LiFePO4 battery brand for your needs.

Top 10 Best LiFePO4 Battery Brands 2024

-

-

- Top 10 Best LiFePO4 Battery Brands/Suppliers in South Africa 2024

- Top 10 Best LiFePO4 Battery Brands/Suppliers in Saudi Arabia 2024

- Top 10 Best LiFePO4 Battery Brands/Suppliers in Germany 2024

- Top 10 Best LiFePO4 battery Brands/Suppliers in UK 2024

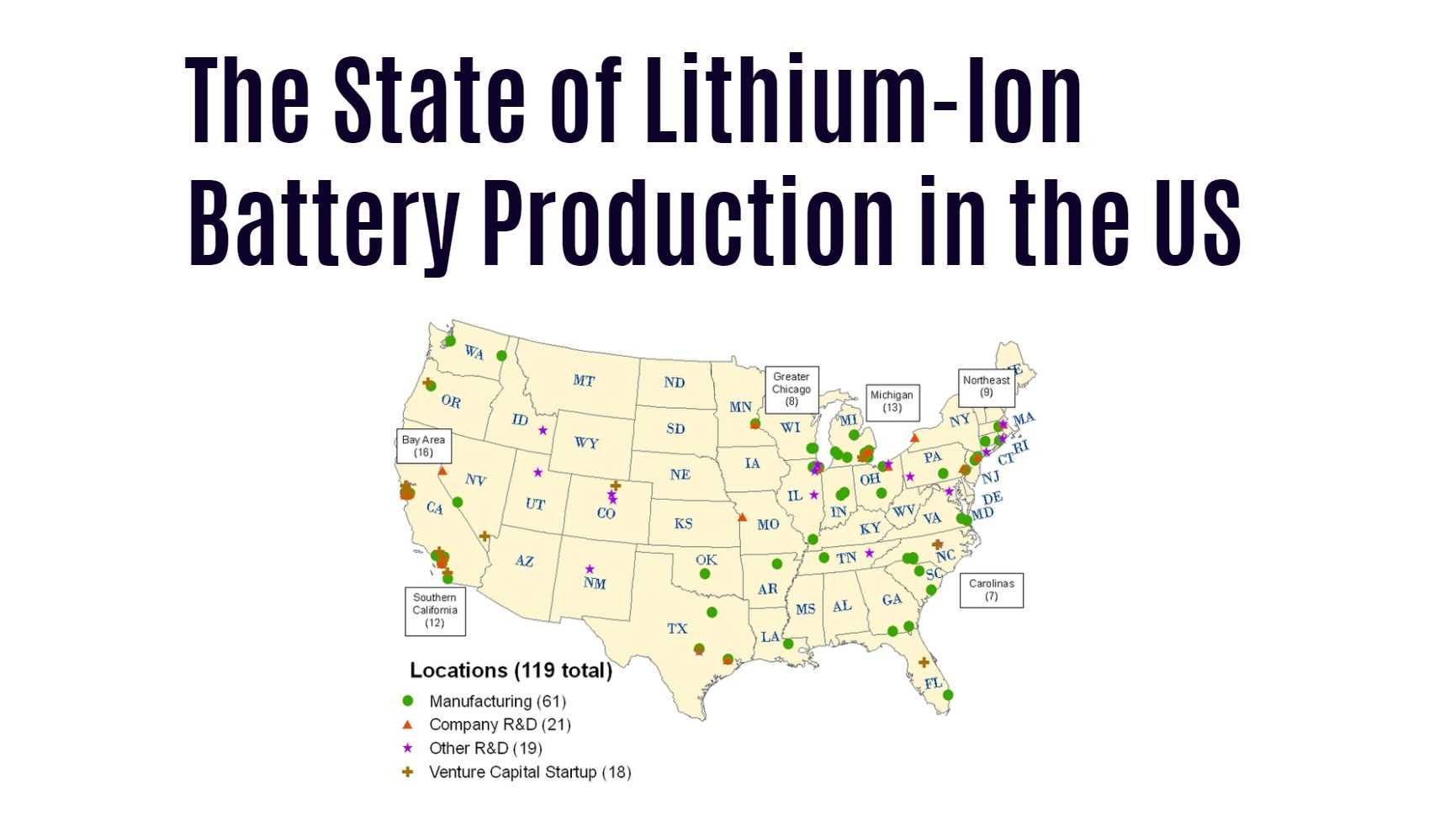

- Top 10 Best LiFePO4 battery Brands/Suppliers in the USA 2024

- Redway Top 3 Best-selling Models in 2024

- Top 5 Best Selling LiFePO4 Batteries 2023 from Redway

- South Africa Top-5 Best-Selling Lithium Batteries in 2024

- Kuwait Top-5 Best-Selling Lithium Battery Packs in 2024 by Redway

-

How to Choose the Right LiFePO4 Battery

When choosing a LiFePO4 battery, consider your application (RV, solar power, etc.), battery capacity in Ah, and voltage (12V, 24V, etc.). Check manufacturer reputation, balance price with quality, and ensure it meets your performance needs. This approach ensures reliability and suitability for your specific requirements.

- Identify the application: RV, boat, solar power storage, etc., to match specific requirements.

- Consider battery capacity in ampere-hours (Ah) based on energy needs and usage patterns.

- Choose the right voltage (12V, 24V, 48V) to meet your system’s specifications.

- Check the manufacturer‘s reputation through customer reviews and feedback.

- Factor in the price but prioritize long-term quality to save money over time.

- Ensure the selected LiFePO4 battery aligns with your needs for reliable performance.

By considering these factors when choosing a LiFePO4 battery, you can ensure that you select one that meets your needs and provides reliable performance over time.

Conclusion

LiFePO4 batteries are a better choice than regular batteries. They last longer, work better, and are better for the environment. When picking one, think about what you need in terms of power and voltage. Be careful handling them, but with the right precautions, they’re great for RVs and boats. Investing in a good one is smart for long-lasting and affordable energy storage. This guide helps you understand what to expect from different brands and models of these awesome batteries!

FAQs

Can you mix different brands of LiFePO4 batteries?

Can I mix 100Ah and 200Ah batteries?

While it is possible to mix 100Ah and 200Ah batteries, it is generally not recommended. Mixing batteries of different capacities can lead to imbalances, strain on both batteries, and reduced performance. It can also result in risks such as overcharging or undercharging. To ensure optimal performance and longevity, it is advisable to use batteries with matching capacities.