Tesla has been drawing this pie for two years, and the details of 4680 are finally revealed? No-pole ear or all-pole ear, is mass production out of shape? Recently we talked about BYD’s CTB and Ningde Kirin battery, and we are about to talk about 4680. YouTube blogger The Limiting Factor just updated the dismantling video of 4680 battery. The internal details of 4680 are really exposed for the first time.

Brand new positive and negative electrode structure

Before the official start, we still need to clarify the background information of this 4680 battery dismantling.

First of all, the blogger The Limiting Factor also said that this cell was made 6 months ago, and it cannot be ruled out that it is different from the final mass-produced version.

Teslas produced in different regions of the world may not have the same cell technology. After all, the recent battery industry is too complicated and changes very fast. Berlin’s 4680, the water-cooled plate is a horizontal layout:

By the time of the Texas factory in March this year, the newly announced 4680 structure, the water cooling plate has become a vertical layout:

In the meeting of 100 people in March, the Kirin battery in the PPT of Dr. Wu Kai of CATL, the battery cell still stood upright, and when it was officially announced in June, it became upside down.

No one knows whether the batteries disassembled this time will change again.

Moreover, the state of the electrolyte in the cell is not correct, and the open circuit voltage is only about 0.1V.

There is no electrolyte flow out when it is disassembled, only some crystal-like white objects.

The previous cylindrical batteries, like the 5th and 7th batteries, are in line with our intuition – the protruding top is the positive pole, and the bottom disc is the negative pole.

The positive and negative poles should be far enough apart to prevent short circuits. But this 4680 is so different. In order to facilitate the welding of high-voltage connecting wires, the raised pole above is the positive pole, while the entire shell becomes the negative pole.

From top to bottom, everything is charged, but the bottom plate is not charged.

Between the positive and negative electrodes, the closest place is less than a millimeter, separated by a thin insulating layer in the middle. Such a battery, if you touch anything here, it will be short-circuited.

Cylindrical batteries, originally a battery product in the 3C field, were introduced into the power battery of cars by Tesla. In just ten years, it has evolved into a battery cell completely designed for the CTC integrated battery pack. The industry changes too fast.

No lugs/full lugs, and 100% restored collector plate

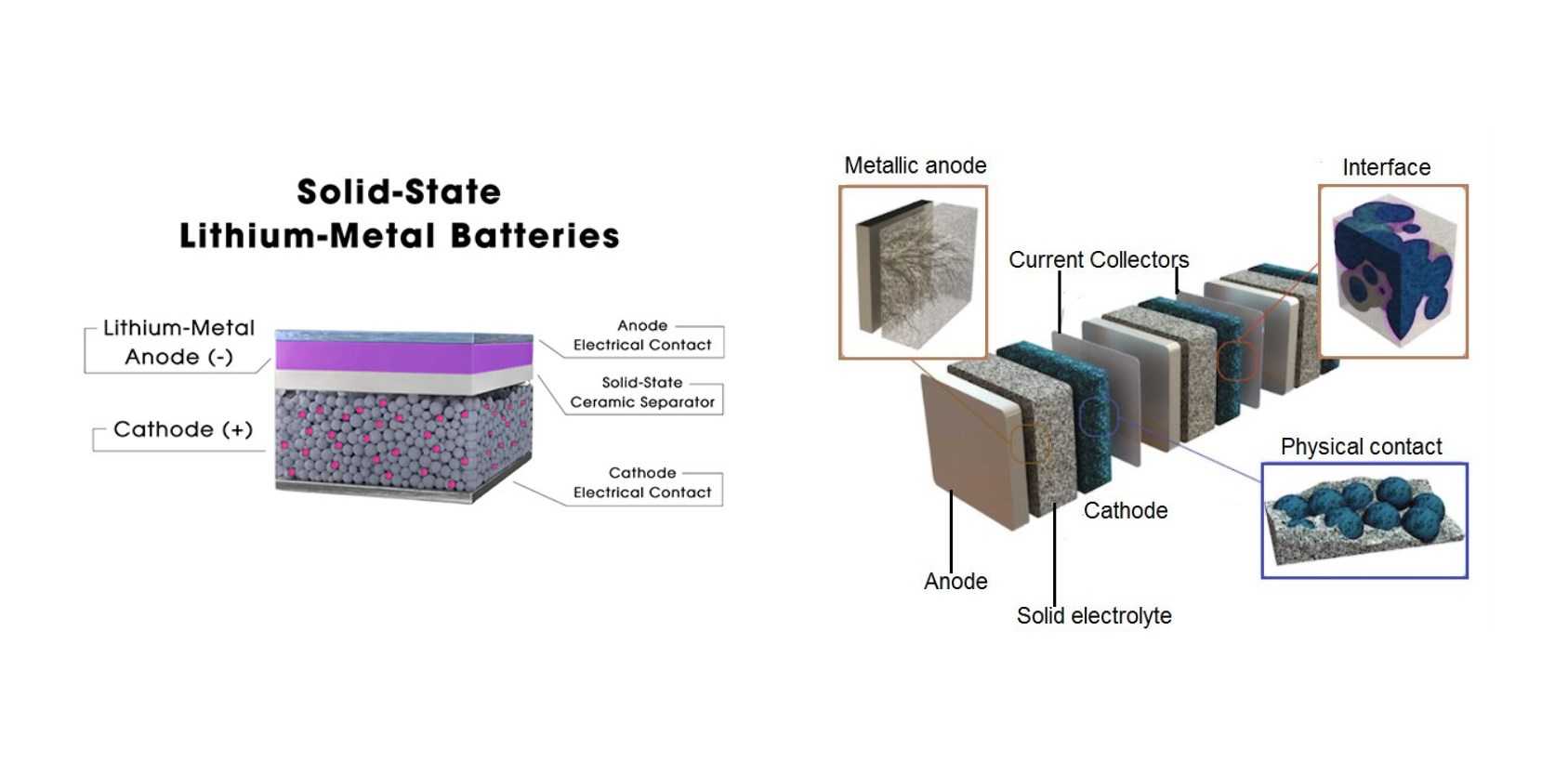

How is it realized in the battery, such a positive and negative electrode structure?

Before explaining this, let’s talk about the new design of the ear.

I believe that on the Tesla Battery Day almost two years ago, everyone was most impressed by the structure of this all-pole ear.

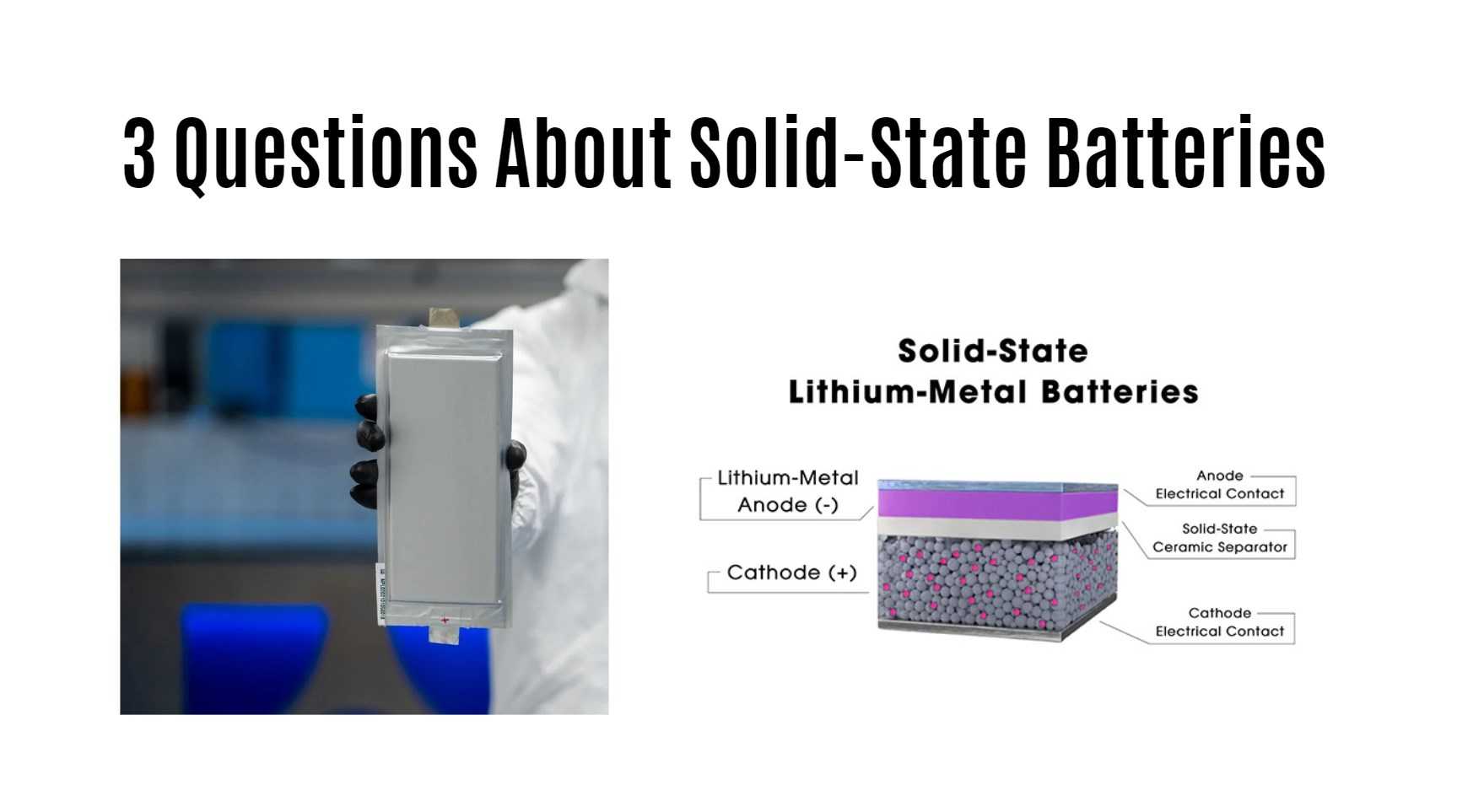

The so-called pole ear is the conductor that leads out the positive or negative pole from the battery core.

In a traditional wound battery, a protruding “ear” is welded to one end or the middle of the electrode foil to pass the current out. This ear is also like a small label, which is called “Tab” in English, which means label.

Cut the battery and disassemble the core of the battery. There are four layers of film stacked together. From top to bottom, there is a separator, a negative electrode, another layer of separator, and a positive electrode. This is the same as a roll of toilet paper, the thicker the cylinder, the longer the paper inside.

According to preliminary measurements, the length of the positive pole is about 3 meters 3, the length of the negative pole is 3 meters 4, and the height is less than 80mm.

If the traditional tab mode is used, the chemical reaction that occurs here, the current should flow to the tab in this way, the longer the distance, the greater the resistance and the greater the heat generation. The 4680 originally became thicker, so the heat cannot go out, and heat dissipation is the biggest problem. If you use the traditional polar ear mode, it will definitely not work.

Tesla’s solution is to cut a row of densely packed, bendable small pieces on the edge of the positive and negative electrodes, so that the current can take a shortcut.

This is like when the primary school is over, the primary school students rush to the school gate while singing “The Lonely Brave”, but they are all blocked at the gate; and 4680 is like directly tearing down the school wall, so the efficiency of school dismissal is naturally much higher.

And these small pieces that can be bent, the positive electrode is an aluminum sheet, and the negative electrode is a copper sheet. If you fold it inward, it is the chrysanthemum.It should be said that after the actual mass-produced cells are disassembled, the degree of restoration of the previous renderings is still very high. After all, there are welding and tampering, so it is impossible to be as neat as the new one. But there is a detail, the outermost and innermost circles of the electrode foil do not actually have cut tabs, so strictly speaking, the term full tab is not entirely accurate, it can probably be called a quarter Three, or four-fifths lug?

The current comes from all directions, so a part is needed to gather the current and send it out. We rewinded the video. When the battery bottom plate was just disassembled, there was such a thing inside. It didn’t have an exact name, and the researchers who disassembled it could only call it Flower. Chinese… Let’s call it “collector plate” for the time being. This part is very critical, and it was only seen in the patent before, and it is the first time in this video that it is shown in kind.

From top to bottom, the battery is the positive pole, the casing, the positive current collector, the winding core, the negative current collector, the insulating material, and the bottom cover.

The collector plates are all six petals, each with 3 long and 2 short five welds, and between the tabs, they are laser welded together, but it is also very simple to distinguish the positive and negative electrodes——

The positive pole is an aluminum plate, which is responsible for summarizing the current and gathering it towards the middle. The position of the petal link is facing outward, because the pole of the positive pole is in the middle;

The negative electrode is a copper plate, which collects the current from the middle and spreads around it, because the shell of the negative electrode is around. This material is the same as that of traditional batteries. I have a cover plate for a square shell battery here, which is also one aluminum and one copper.

According to various information on the Internet, I sorted it out. The whole battery assembly process should be like this – first weld the positive collector plate and the winding core, then put the winding core in with the tank head down, Weld the negative current collector. There is also a hole on the negative collector plate, which is also a channel for welding the positive electrode collector plate in addition to filling the electrolyte. After the winding core is put in, the ultrasonic welding head can be inserted through this hole, go deep into the bottom, and weld the lowermost positive current collecting plate and the pole together. The last step is to cover the bottom plate.

Assistance and Challenges from the Process

Overall, the information provided by the 4680 cell is substantial. Honestly speaking, based on the information available to us at present, the Tesla 4680 battery cell brings both benefits and challenges.

- The design of a full electrode tab reduces the length of the current path, lowers internal resistance, raises the current limit, and supports higher power output and fast charging.

- With reduced internal resistance, there is less heat generation and energy loss, allowing for a higher proportion of usable energy.

- For production line processes, there is no need for welding electrode tabs, eliminating interruptions during coating and simplifying the coating production process.

At the same time, it also presents some new challenges:

Firstly, higher requirements for electrode coating. With the full electrode tab design, battery coating requires leaving blank spaces at the edges, demanding higher precision from the coating equipment. Inadequate coating precision might lead to problems during shaping and welding of the electrode tabs.

Secondly, higher consistency is demanded for electrode tab shaping. During the process of cutting and shaping the electrode tabs, metal debris may be produced, posing a risk of short circuits in the battery. Additionally, there are stricter requirements for the flatness of the end faces; inadequate precision can affect the yield of collector plate welding. The delayed mass production of the 4680 cell is partly due to insufficient production line yield, apart from thermal management issues.

Lastly, laser welding of the collector plate requires high precision and stability. On the petals of the collector plate, the 30 weld seams connecting the electrode tabs are very precise in size and cannot contain any welding slag, necessitating laser welding. If the laser welding process is unstable, it may result in virtual welding or excessive temperature, damaging the separator. Further disclosure of these process-related details awaits official information from Tesla.