Does BMS Limit Charging Voltage? Battery Management Systems in Charging Lithium Batteries

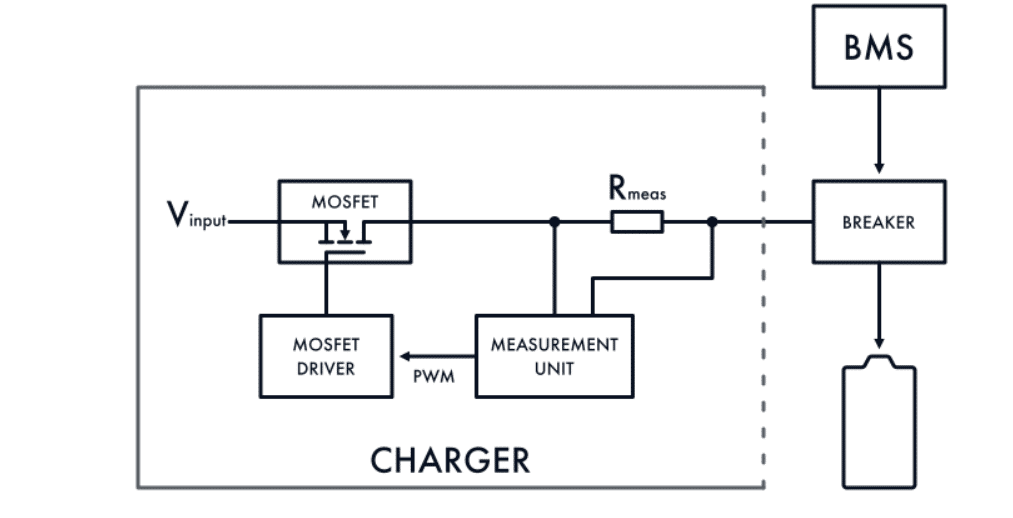

In the realm of lithium battery technology, the Battery Management System (BMS) plays a crucial role in ensuring safety, efficiency, and longevity. One of the key functions of a BMS is to manage the charging process, including limiting the charging voltage. This article delves into how a BMS operates in charging lithium batteries, its importance, and the implications of charging voltage limitations.

Understanding Battery Management Systems (BMS)

A Battery Management System is an electronic system that monitors and manages rechargeable batteries or battery packs. It performs several vital functions:

- Monitoring: The BMS continuously tracks parameters such as voltage, current, temperature, and state of charge (SoC) for each cell in the battery pack.

- Balancing: Ensures that all cells within the battery pack are charged and discharged evenly to prolong battery life.

- Protection: Safeguards against overcharging, over-discharging, and thermal runaway.

The Role of BMS in Charging Lithium Batteries

1. Voltage Regulation

One of the primary roles of a BMS during the charging process is to regulate the voltage applied to each cell:

- Limiting Charging Voltage: The BMS ensures that the charging voltage does not exceed a predetermined threshold. For most lithium-ion batteries, this threshold is typically around 4.2 volts per cell. Exceeding this voltage can lead to overheating, reduced lifespan, or even catastrophic failure.

- Cell Balancing: In multi-cell configurations, the BMS balances the voltage across all cells to ensure that no individual cell is overcharged. This balancing act is crucial for maintaining overall battery health.

2. Current Control

In addition to managing voltage, the BMS also regulates the current flowing into the battery:

- Charging Current Limits: The BMS can limit the maximum charging current based on factors such as temperature and SoC. This feature helps prevent overheating and ensures safe charging rates.

- Adaptive Charging Profiles: Advanced BMS units can adjust charging profiles dynamically based on real-time data, optimizing performance while protecting battery health.

Importance of Limiting Charging Voltage

1. Safety

- Preventing Thermal Runaway: Overcharging can lead to thermal runaway, a condition where excessive heat causes a battery to fail catastrophically. By limiting charging voltage, the BMS mitigates this risk effectively.

- Avoiding Cell Damage: Consistently exceeding recommended voltage levels can damage individual cells within a battery pack, leading to reduced capacity and lifespan.

2. Longevity

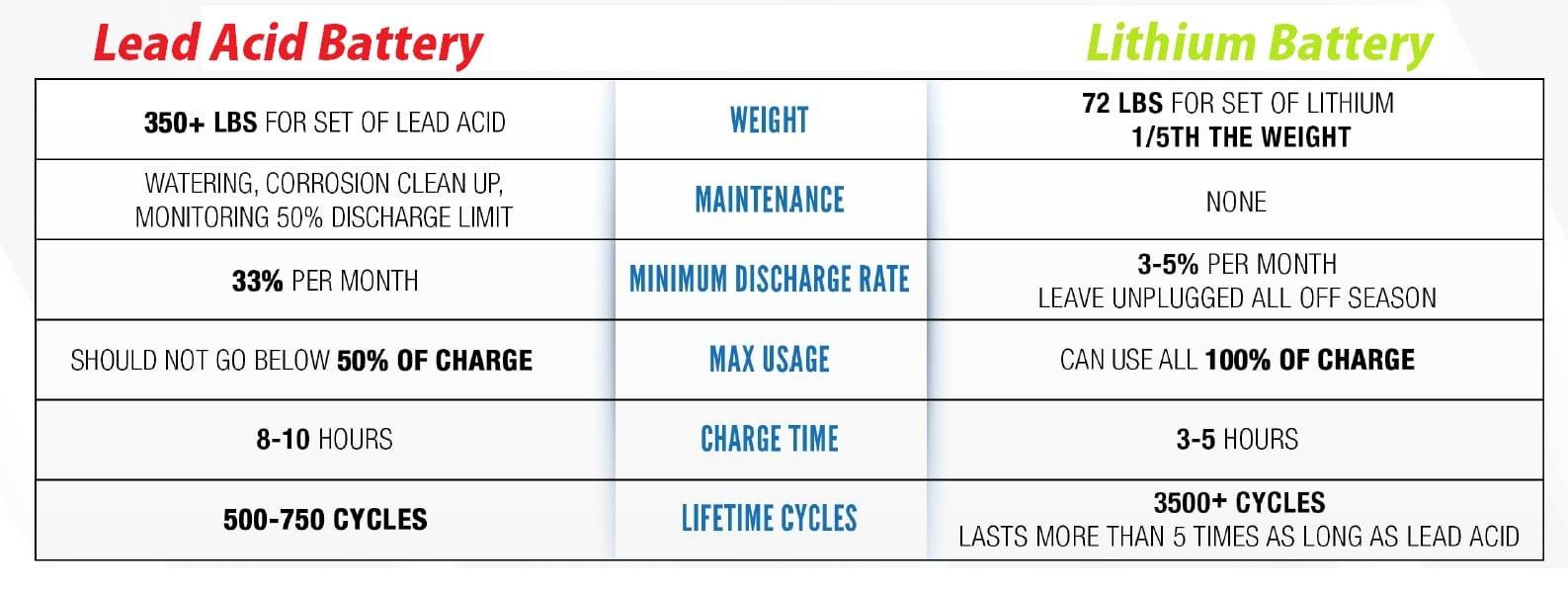

- Extending Battery Life: Maintaining proper voltage levels during charging significantly extends the overall life of lithium batteries. A well-managed charging process can increase cycle life by hundreds or even thousands of cycles.

- Preserving Capacity: Limiting voltage helps preserve the capacity of lithium batteries over time. Batteries that are frequently overcharged may experience capacity fade more rapidly than those managed properly.

Best Practices for Using a BMS with Lithium Batteries

To maximize the benefits of a Battery Management System in your lithium battery setup, consider these best practices:

1. Choose a Quality BMS

Invest in a high-quality BMS designed specifically for your type of lithium battery. Look for features such as:

- Overvoltage protection

- Temperature monitoring

- Balancing capabilities

2. Regular Monitoring and Maintenance

Regularly check your battery system for any signs of malfunction or degradation:

- Monitor SoC and voltage levels to ensure they remain within safe limits.

- Inspect connections and wiring for signs of wear or corrosion.

3. Follow Manufacturer Guidelines

Always adhere to manufacturer guidelines regarding charging voltages and currents. Each battery chemistry may have specific requirements that should be followed for optimal performance.

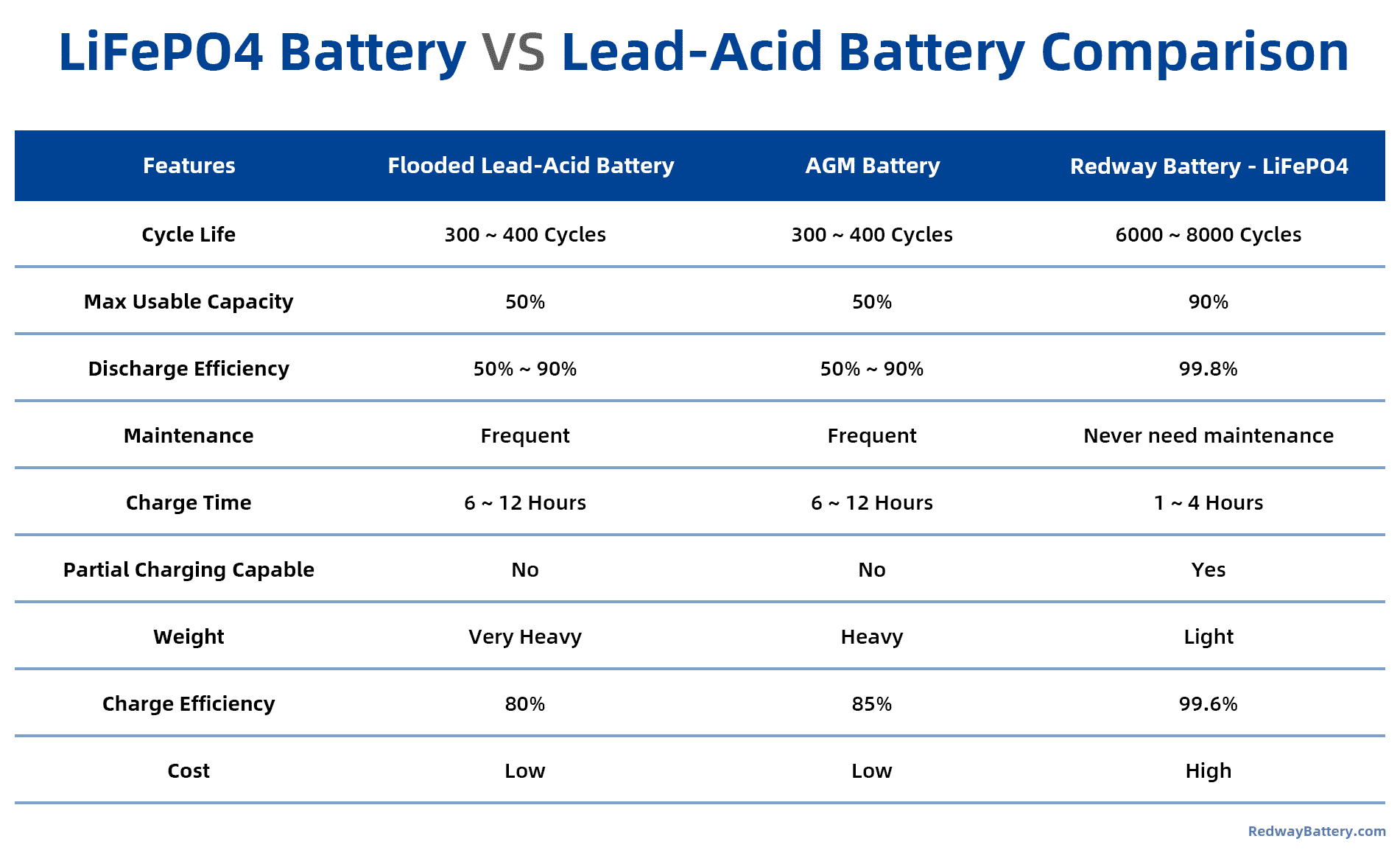

Data Chart: Comparison of Charging Characteristics by Battery Type

| Feature | Lithium Iron Phosphate (LiFePO4) | Lithium Cobalt Oxide (LCO) | Nickel Manganese Cobalt (NMC) |

|---|---|---|---|

| Maximum Charging Voltage | 3.6 – 3.65 V per cell | 4.2 V per cell | 4.2 V per cell |

| Recommended Charging Current | Up to 1C | Up to 0.5C | Up to 1C |

| Cycle Life | 3,000 – 5,000 cycles | 500 – 1,500 cycles | 1,500 – 2,500 cycles |

| Thermal Stability | Excellent | Moderate | Good |

FAQs About BMS and Charging Lithium Batteries

Does a BMS prevent overcharging?

Yes, a BMS actively monitors and limits both charging voltage and current to prevent overcharging.

Can I use any charger with my lithium battery?

No, using a charger not designed for your specific battery type can lead to improper charging and potential damage.

How often should I check my BMS?

It’s advisable to monitor your BMS regularly during operation and perform maintenance checks every few months.

Latest News on Battery Management Systems

Recent developments in Battery Management Systems focus on enhancing safety features and improving efficiency:

- New algorithms are being developed that allow for smarter energy management based on real-time usage patterns.

- Advances in wireless communication technologies are enabling remote monitoring capabilities for better oversight of battery health.

Conclusion

In conclusion, a Battery Management System plays an essential role in managing the charging process of lithium batteries by limiting charging voltage and ensuring safety and longevity. By understanding how a BMS functions and implementing best practices for usage, you can maximize your lithium battery’s performance and lifespan.For customized lithium solutions tailored specifically to your needs—whether for automotive applications or renewable energy systems—contact Redway Battery today for a quick quote!