Exploring Real-World Applications of LiFePO4 Batteries in Forklifts

In recent years, LiFePO4 (Lithium Iron Phosphate) batteries have become increasingly prevalent in the forklift industry, driven by their superior performance, longevity, and maintenance advantages. This article delves into various real-world applications of LiFePO4 batteries in forklifts, showcasing how this technology is transforming material handling operations across diverse sectors.

LiFePO4 batteries are increasingly used in forklifts across various industries such as warehousing, manufacturing, and logistics. Their fast charging capabilities and long cycle life make them ideal for operations requiring consistent power without downtime.

1. Counterbalanced Forklifts

Counterbalanced forklifts are a staple in many industrial settings, providing powerful lifting capabilities for heavy loads. LiFePO4 batteries are making significant strides in this category due to their high energy density and extended operational life.

- Hyster J155-360XD Series: Hyster offers 80V LiFePO4 batteries for their J155-360XD series of 4-wheel electric counterbalanced forklifts. These batteries are engineered to support heavy-duty applications with long runtimes and high energy output, making them ideal for demanding industrial environments.

- Toyota 8-Series: Toyota has integrated 80V LiFePO4 batteries into their 8-Series 4-wheel electric forklift models. This innovation enhances performance and efficiency, providing a noticeable improvement over traditional lead-acid batteries. The advanced battery technology ensures robust power delivery and reduced downtime.

2. Narrow Aisle Forklifts

Narrow aisle forklifts are essential for maximizing storage space and enhancing maneuverability in tight warehouse environments. LiFePO4 batteries offer several benefits for these specialized machines.

- Crown RM 6000 Series: Crown’s RM 6000 Series narrow aisle reach trucks are equipped with 48V LiFePO4 batteries. These batteries deliver extended run times and rapid charging capabilities, significantly boosting productivity and reducing operational interruptions.

- Jungheinrich EKX Series: Jungheinrich’s EKX 410k and EKX 513k very narrow aisle (VNA) forklifts utilize 80V LiFePO4 batteries. The compact design of these batteries ensures high energy density, allowing for efficient performance in compact and space-constrained environments.

3. Pallet Jacks and Stackers

Pallet jacks and stackers are critical for moving and stacking pallets in various settings, including warehouses and retail spaces. LiFePO4 batteries enhance these machines’ efficiency and operational reliability.

- Raymond 8210 Pacer and 8400 Orderpicker: Raymond’s 8210 Pacer pallet jack and 8400 Orderpicker are powered by 24V LiFePO4 batteries. These batteries eliminate the need for watering and equalization, offering a maintenance-free solution that simplifies fleet management.

- Yale MP20-25 Series: Yale’s MP20-25 series electric pallet trucks are equipped with 24V LiFePO4 batteries. These batteries support opportunity charging and provide a maintenance-free operation, contributing to increased uptime and lower total cost of ownership.

Benefits of LiFePO4 Batteries in Forklifts

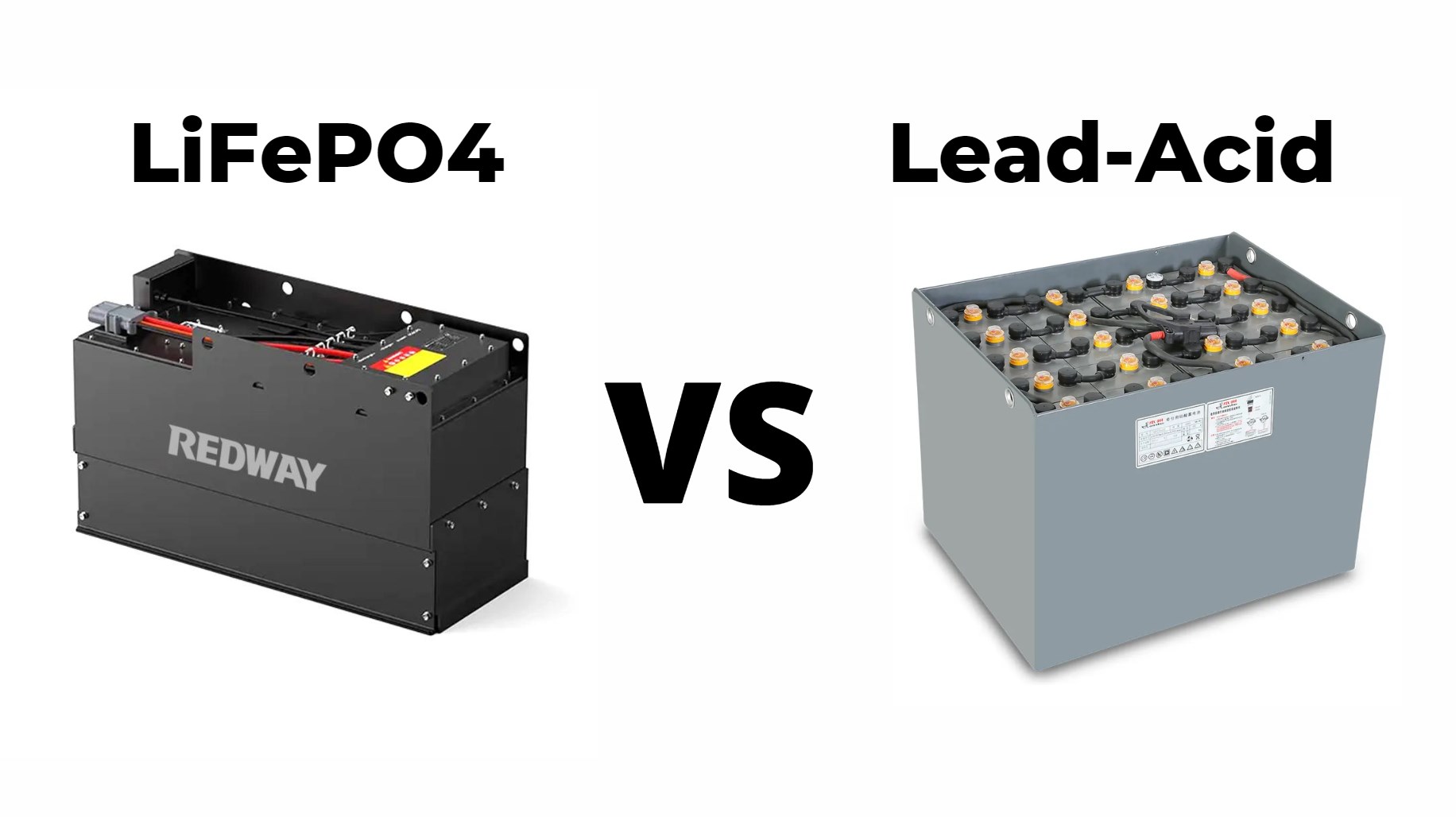

LiFePO4 batteries offer several advantages over traditional lead-acid batteries, which are particularly beneficial in forklift applications:

- High Energy Density: LiFePO4 batteries deliver more energy per unit of weight, allowing forklifts to operate longer on a single charge. This efficiency reduces the need for frequent recharging and increases overall productivity.

- Extended Lifespan: These batteries have a longer life cycle compared to lead-acid batteries, with many lasting up to 5,000 cycles. This longevity translates to reduced replacement costs and less frequent maintenance.

- Maintenance-Free Operation: Unlike lead-acid batteries, LiFePO4 batteries require minimal maintenance. They do not need regular watering or equalization, which simplifies battery management and lowers operational costs.

- Faster Charging: LiFePO4 batteries charge faster than their lead-acid counterparts, minimizing downtime and allowing for quick turnaround in busy environments.

- Safety and Stability: LiFePO4 technology is known for its safety features and thermal stability. The batteries are less prone to overheating and thermal runaway, providing a safer solution for industrial applications.

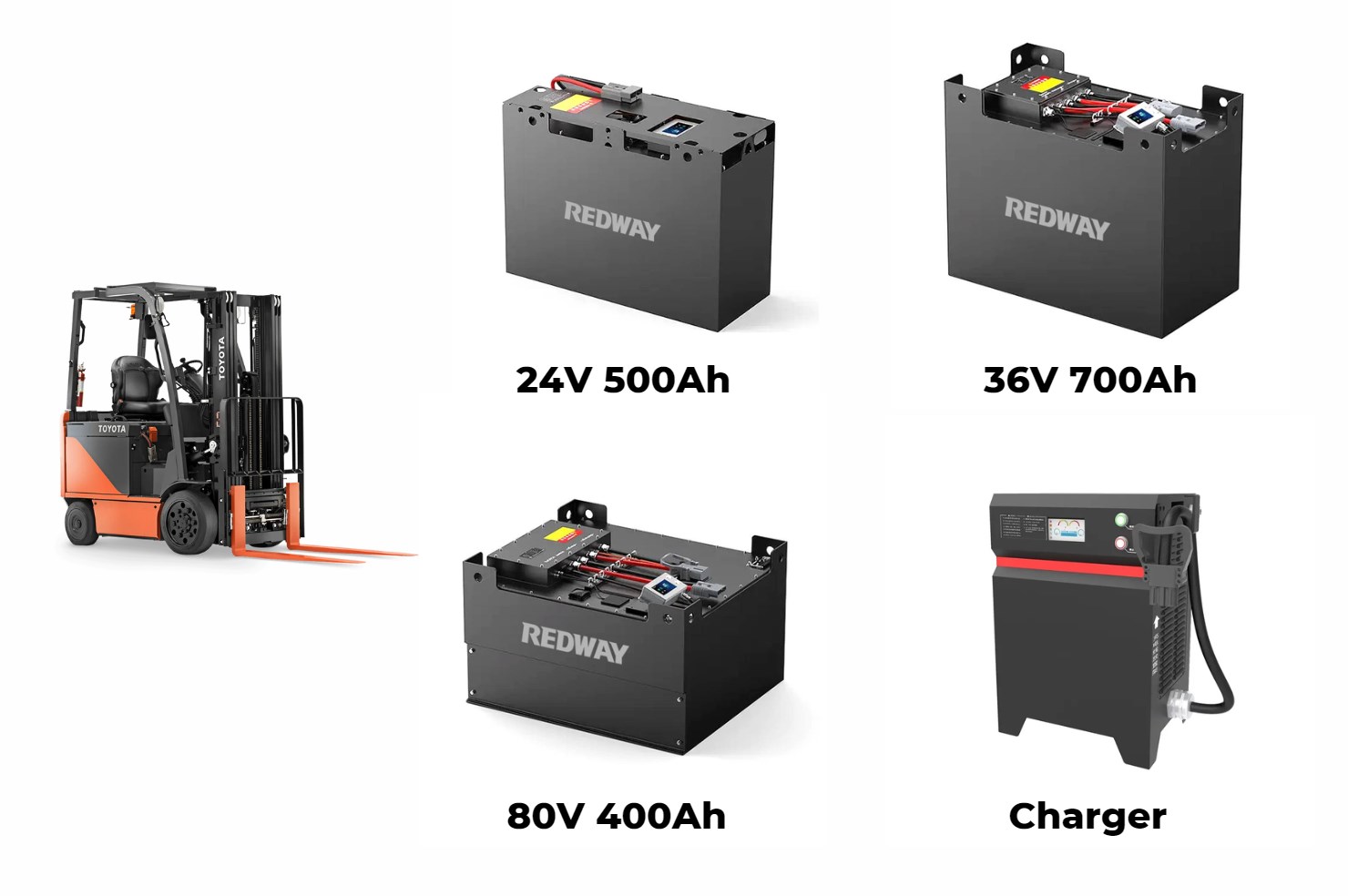

36v 700ah forklift lfp battery

Conclusion

The integration of LiFePO4 batteries into forklift applications represents a significant advancement in material handling technology. From counterbalanced forklifts to narrow aisle reach trucks and pallet jacks, these batteries are enhancing performance, efficiency, and safety across various sectors. With their high energy density, extended lifespan, and maintenance-free operation, LiFePO4 batteries are poised to become the standard choice for modern forklift fleets.

As the forklift industry continues to evolve, embracing LiFePO4 battery technology offers substantial benefits in operational efficiency and cost-effectiveness. By understanding and leveraging these advantages, businesses can optimize their material handling operations and achieve greater productivity and reliability.

FAQs

What Safety Measures Should Be Taken When Using LiFePO4 Forklift Batteries?

Do LiFePO4 Batteries Require Maintenance?

What is the Typical Cost of a LiFePO4 Forklift Battery?

Comparing Maintenance Costs: LiFePO4 Batteries vs. Lead-Acid Batteries

Exploring Real-World Applications of LiFePO4 Batteries in Forklifts

Industries Benefiting from LiFePO4 Forklift Batteries

What is LiFePO4 Technology?

The Evolving Market for Forklift Batteries

What Are the Latest Advancements in LiFePO4 Battery Technology?

How Does Fast Charging Impact Battery Life?

Types of Chargers for LiFePO4 Forklift Batteries

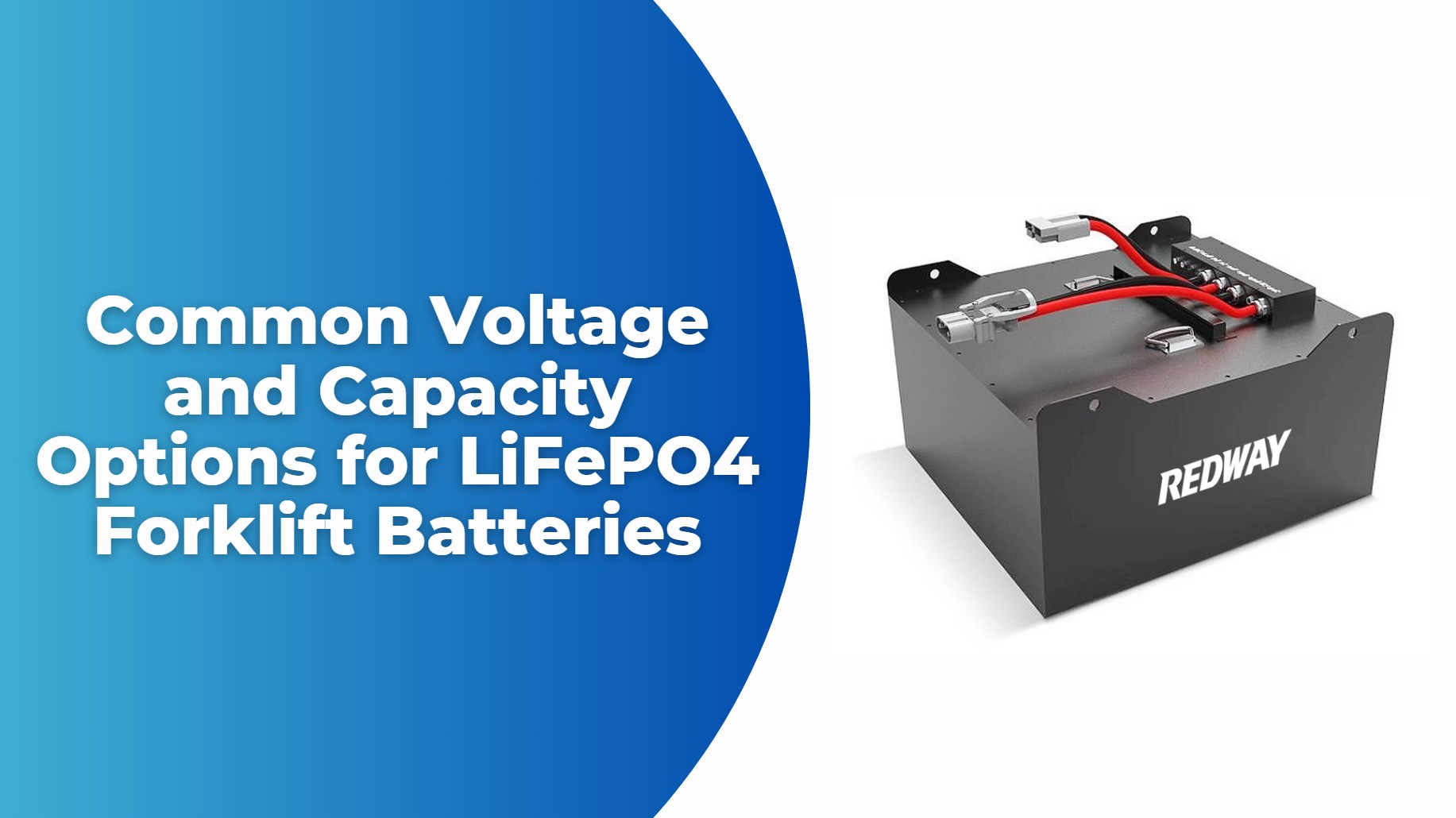

Common Voltage and Capacity Options for LiFePO4 Forklift Batteries

Comparing LiFePO4 and Lead-Acid Batteries: A Comprehensive Analysis