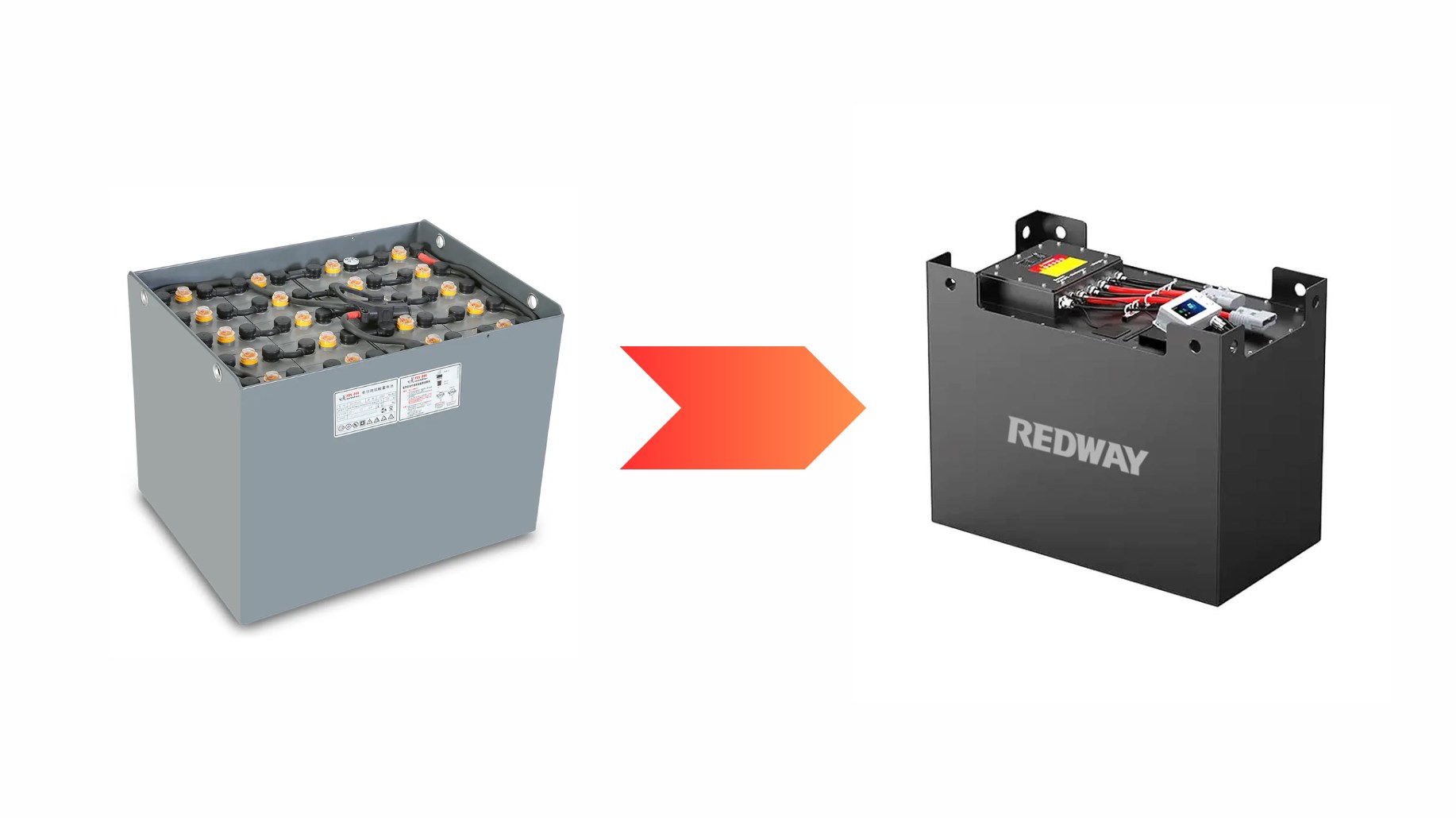

Yes, LiFePO4 batteries can replace lead-acid batteries in existing forklifts, often as a drop-in replacement. However, modifications to chargers, wiring, and sometimes counterweight are needed to ensure safety and efficiency. Redway Battery LiFePO4 solutions are designed for seamless retrofits, enabling faster charging, maintenance-free operation, and long-term cost savings without compromising forklift performance.

How Do Voltage Requirements Affect Forklift Battery Replacement?

LiFePO4 and lead-acid batteries are available in standard forklift voltages like 24V, 36V, and 48V. It is crucial to match the replacement LiFePO4 battery voltage to the forklift system. Using a mismatched voltage can damage electrical components or reduce performance. Always verify specifications before installation.

Why Is a Dedicated LiFePO4 Charger Necessary?

LiFePO4 batteries require chargers with specific charging profiles that differ from lead-acid batteries. Using the wrong charger may damage the battery or create safety hazards. Redway Battery chargers are tailored to LiFePO4 technology, ensuring safe and optimal charging while enabling opportunity charging for increased forklift uptime.

Wholesale lithium golf cart batteries with 10-year life? Check here.

How Does Physical Size and Weight Impact Battery Replacement?

LiFePO4 batteries are significantly lighter than lead-acid batteries. While they often fit the existing battery compartment, forklifts may need additional ballast or brackets to maintain proper weight distribution and stability. Proper weight management ensures safe operation and preserves forklift handling characteristics.

Physical Fit and Weight Chart

Want OEM lithium forklift batteries at wholesale prices? Check here.

| Battery Type | Approximate Weight | Notes |

|---|---|---|

| Lead-Acid 48V 300Ah | 700 lbs | Original forklift battery |

| LiFePO4 48V 300Ah | 400 lbs | Lighter, may require ballast |

What Electrical Connection Considerations Are Needed?

Verify that the LiFePO4 battery terminals match the forklift’s wiring and connectors. Adapters or new cables may be required if there is a mismatch. Ensuring correct electrical connections prevents voltage drops, overheating, and potential damage to the battery and forklift system.

How Does a Battery Management System (BMS) Protect LiFePO4 Batteries?

LiFePO4 batteries include an integrated or compatible BMS to monitor voltage, temperature, and charge levels. The BMS prevents overcharging, deep discharge, and short circuits, ensuring safe and efficient operation. Redway Battery LiFePO4 solutions come with advanced BMS systems to maximize safety and battery lifespan.

What Are the Operational Benefits of Switching to LiFePO4?

LiFePO4 batteries enable opportunity charging and faster full charges, reducing forklift downtime. They offer a longer cycle life, consistent voltage output, and stable performance throughout shifts. Switching to LiFePO4 improves operational efficiency, reduces maintenance, and lowers long-term costs.

How Does Reduced Maintenance Improve Workplace Safety?

Unlike lead-acid batteries, LiFePO4 batteries are sealed, do not emit hazardous gases, and require no watering. This reduces exposure to corrosive acid, eliminates the need for ventilation systems, and lowers workplace safety risks. Redway Battery’s LiFePO4 packs simplify maintenance and improve the safety profile of forklift operations.

What Are the Cost Implications of Converting to LiFePO4?

Although LiFePO4 batteries have higher upfront costs, savings are realized through fewer battery replacements, lower energy consumption, minimal maintenance, and less operational downtime. A comprehensive total cost of ownership analysis often shows LiFePO4 batteries from Redway Battery provide superior long-term value.

Redway Battery Expert Views

“Retrofitting forklifts with LiFePO4 batteries is a strategic investment. While minor adjustments are needed, the benefits in uptime, safety, and total cost savings are substantial. Redway Battery ensures that every LiFePO4 conversion meets rigorous safety standards and delivers consistent performance for modern warehouse operations,” says a Redway Battery expert.

Conclusion

LiFePO4 batteries can successfully replace lead-acid batteries in existing forklifts with careful attention to voltage, chargers, weight, and electrical compatibility. Redway Battery LiFePO4 solutions provide a seamless retrofit option that increases uptime, reduces maintenance, improves safety, and optimizes long-term costs. Transitioning to LiFePO4 is a forward-looking investment in efficiency and reliability.

FAQs

Can LiFePO4 batteries fit in any forklift?

Most LiFePO4 batteries are designed to match standard lead-acid sizes, but weight distribution and terminal compatibility must be checked.

Do LiFePO4 batteries require special chargers?

Yes, a dedicated LiFePO4 charger is required for safe and efficient operation.

Will forklift performance change after switching?

LiFePO4 batteries maintain stable voltage and consistent performance, often improving efficiency.

Are LiFePO4 batteries safer than lead-acid?

Yes, they are sealed, do not emit hazardous gases, and reduce maintenance-related hazards.

Is retrofitting expensive?

Initial cost is higher, but long-term savings from reduced downtime, maintenance, and energy use often offset upfront investment.