LiFePO4 batteries are significantly lighter than lead-acid batteries, often weighing about 50% less for equivalent capacities. This weight reduction enhances forklift maneuverability and reduces energy consumption during operation, contributing to overall efficiency improvements.

When it comes to selecting the right battery for various applications, understanding the weight differences between LiFePO4 (Lithium Iron Phosphate) batteries and lead-acid batteries is crucial. This article delves into the reasons behind the significant weight disparity and explores the implications for different use cases.

Understanding Battery Technologies

LiFePO4 Batteries: An Overview

LiFePO4 batteries represent a cutting-edge technology in the realm of lithium-ion batteries. Known for their high energy density and long cycle life, these batteries have become increasingly popular across a range of applications. The energy density of LiFePO4 batteries allows them to store more energy in a smaller, lighter package compared to traditional lead-acid batteries. This feature is especially advantageous in contexts where weight and space are critical considerations.

Lead-Acid Batteries: Traditional Yet Bulky

Lead-acid batteries have been a staple in energy storage for over a century. Despite their robustness and relatively low cost, they are characterized by their substantial weight and larger physical size. The energy density of lead-acid batteries is significantly lower than that of LiFePO4 batteries, necessitating a larger battery to achieve comparable energy storage. This intrinsic weight disadvantage impacts various aspects of their usability.

Comparing Weight: LiFePO4 vs. Lead-Acid Batteries

Weight Characteristics of LiFePO4 Batteries

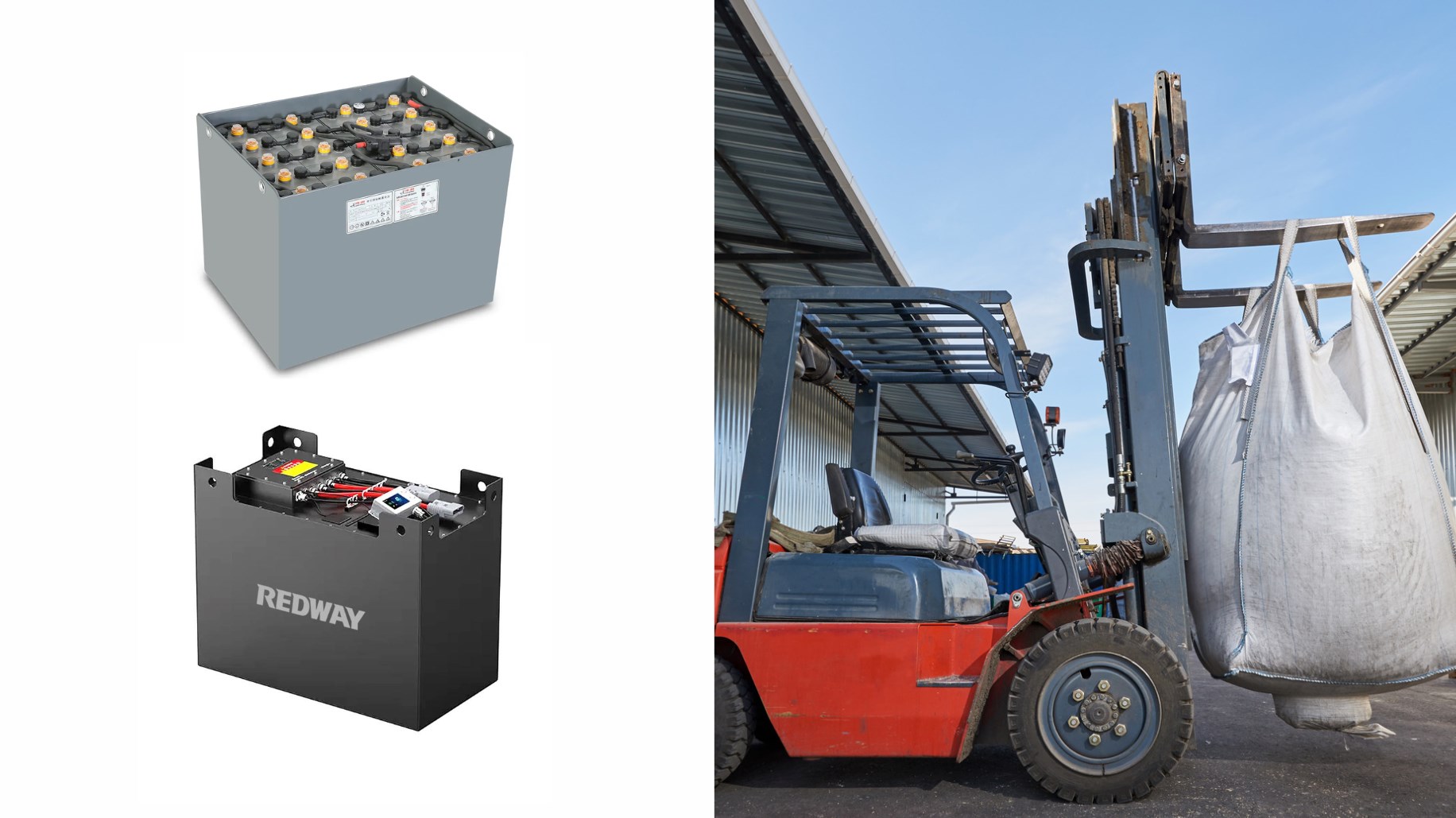

LiFePO4 batteries are renowned for their lightweight construction. For instance, a typical 12V LiFePO4 battery with a capacity of 100Ah might weigh around 12-15 kg (26-33 lbs). This weight is a result of the battery’s efficient energy storage capabilities and the use of lightweight materials such as aluminum and plastic composites in its construction. The lightweight nature of LiFePO4 batteries is a significant advantage in applications where portability and ease of handling are paramount.

Weight Characteristics of Lead-Acid Batteries

In contrast, lead-acid batteries are substantially heavier. A comparable 12V lead-acid battery with the same capacity (100Ah) can weigh between 25-30 kg (55-66 lbs). The heavier weight is due to the battery’s construction, which involves lead plates and sulfuric acid. These materials contribute to the overall mass, making lead-acid batteries less ideal for applications where weight constraints are a concern.

Implications of Weight Differences

Impact on Portable Applications

The reduced weight of LiFePO4 batteries translates to numerous advantages in portable applications. For example, in electric vehicles (EVs), the lighter weight of LiFePO4 batteries contributes to better energy efficiency and performance. Reduced battery weight means less strain on the vehicle’s suspension and motor, leading to improved overall efficiency and range. Similarly, in solar power systems, the lightweight nature of LiFePO4 batteries simplifies installation and handling, making them more suitable for residential and commercial setups where space and weight are limited.

Advantages in Handling and Transportation

The ease of handling and transportation associated with LiFePO4 batteries is another crucial benefit. For portable electronics, such as laptops and power tools, a lighter battery not only enhances mobility but also reduces user fatigue. In contrast, the bulkiness of lead-acid batteries can make handling cumbersome, often requiring specialized equipment for transportation and installation.

Cost Considerations

Economic Aspects of LiFePO4 Batteries

While LiFePO4 batteries offer superior weight advantages, they come with a higher initial cost compared to lead-acid batteries. However, their longer lifespan and lower maintenance requirements can offset the higher purchase price over time. The cost-benefit analysis should consider not only the upfront expense but also the long-term savings in terms of durability and performance.

Cost Benefits of Lead-Acid Batteries

Lead-acid batteries, despite their weight, remain a cost-effective choice for many applications due to their lower initial purchase price. They are widely available and have a well-established infrastructure for recycling and disposal. However, their shorter lifespan and higher maintenance needs may lead to additional costs over time.

Applications Where Weight Matters

Electric Vehicles (EVs)

In the realm of electric vehicles, the weight of the battery pack directly impacts the vehicle’s range and performance. LiFePO4 batteries are preferred for their ability to provide high energy storage in a lighter package, leading to enhanced driving efficiency and extended range.

Solar Power Systems

For solar power systems, whether in residential or commercial setups, the lightweight nature of LiFePO4 batteries simplifies installation and reduces structural load requirements. This aspect is crucial for rooftop solar installations and mobile solar power systems.

Portable Electronics

In the case of portable electronics like laptops, smartphones, and power tools, the reduced weight of LiFePO4 batteries contributes to better ergonomics and user comfort. The impact on device design and portability makes these batteries a preferred choice for modern technology.

Conclusion

In summary, the weight difference between LiFePO4 and lead-acid batteries is a pivotal factor in determining the suitability of each battery type for various applications. LiFePO4 batteries, with their superior energy density and lightweight design, offer distinct advantages in terms of portability, efficiency, and ease of handling. While lead-acid batteries remain a viable option due to their lower initial cost, their heavier weight and larger size may limit their applicability in scenarios where weight is a critical consideration. Understanding these weight characteristics enables users to make informed decisions based on their specific needs and application requirements.