In the intricate world of energy storage, a silent yet powerful factor dictates the longevity and efficiency of batteries: temperature. This article delves into the heart of this phenomenon, exploring how varying degrees of heat can significantly impact the performance of Lead Acid, Nickel-based, and Lithium-ion batteries. We aim to provide an in-depth analysis that not only educates but also sets a new benchmark for content quality in the field of battery technology.

Understanding the Impact: Temperature’s Effect on Battery Health

Temperature: The Catalyst for Capacity Loss

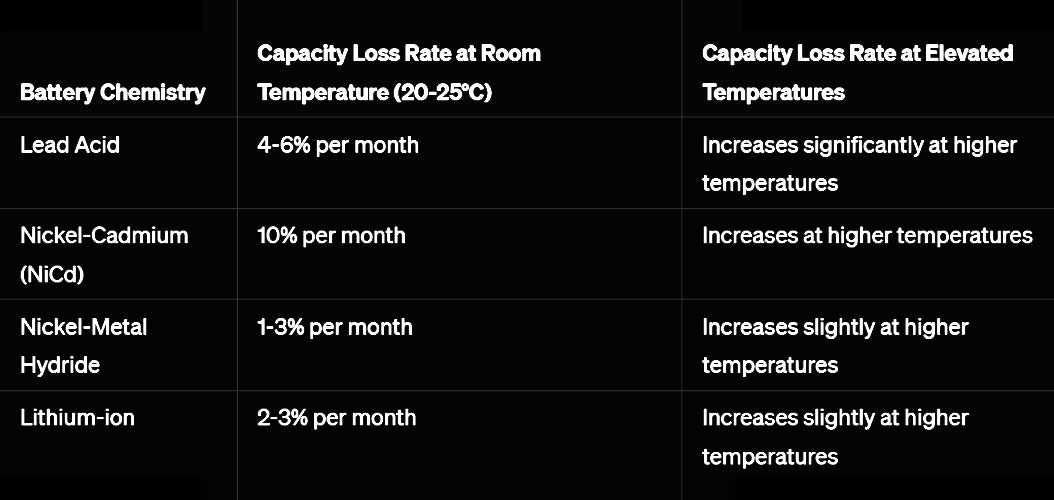

The capacity of a battery to hold charge is not just a function of its design but also a direct response to the thermal environment it operates within. Temperatures that soar can accelerate the degradation process, leading to a rapid decline in a battery’s ability to hold charge.

Lead Acid Batteries: The Sensitivity to Heat

The Doubled Risk at Every 10°C Increase

Lead Acid batteries, widely used for their reliability, face a stark reality when exposed to higher temperatures. For every 10-degree Celsius increase, the risk of capacity loss doubles, underscoring the necessity for stringent temperature control measures.

Nickel-based Batteries: A Comparative Analysis

The Moderate yet Significant Impact

While not as dramatically affected as Lead Acid, Nickel-based batteries, including Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH), still witness an accelerated rate of capacity loss under the influence of elevated temperatures. This comparative analysis highlights the universal sensitivity of batteries to heat.

Lithium-ion Batteries: The Resilient Performers

Lower Loss Rates and the High-Temperature Challenge

Lithium-ion batteries, known for their superior energy density and longevity, exhibit lower capacity loss rates even when subjected to higher temperatures. However, extreme heat remains a threat, capable of increasing the rate of degradation and posing safety concerns.

Optimal Battery Management: The Key to Longevity

Manufacturer Guidelines: The Blueprint for Battery Health

Manufacturers provide detailed temperature guidelines and specifications, which when adhered to, can significantly extend the life and enhance the performance of batteries. Implementing these recommendations is not just advisable but essential for anyone looking to maximize the utility of their battery investments.

Advanced Thermal Management: The Future of Battery Care

Innovative Solutions for Enhanced Performance

As battery technology advances, so does the need for sophisticated thermal management systems. From passive cooling methods to active thermal control technologies, the future of battery care is one that is intimately tied to the ability to regulate temperature effectively.

Conclusion: The Imperative of Temperature Control

In conclusion, the management of temperature is not an optional luxury but a critical necessity for anyone seeking to optimize battery performance. By understanding and applying the principles outlined in this article, users can ensure that their batteries serve them reliably and efficiently for an extended period.