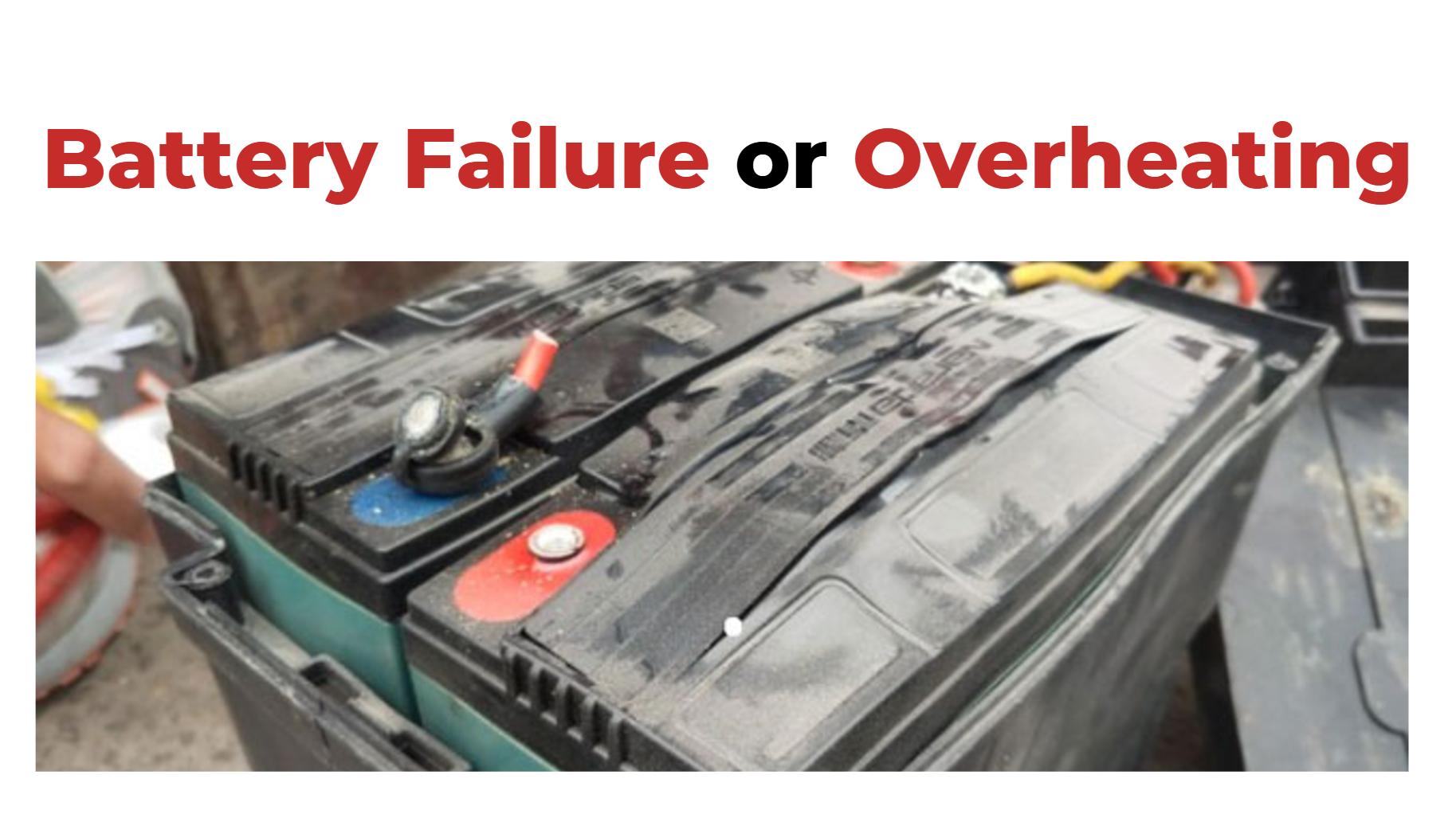

Mitigating risks associated with battery failure or overheating is essential for ensuring the safety and longevity of lithium-ion batteries such as LiFePO4. Users can adopt several preventive measures, including proper charging techniques, implementing battery management systems (BMS), ensuring adequate ventilation, and conducting regular monitoring.

What Are the Key Preventive Measures Against Battery Failure?

To prevent battery failure, users should implement a combination of strategies that include maintaining optimal operating conditions, adhering to manufacturer guidelines, and conducting regular inspections.Preventive Measures Chart:

| Measure | Description |

|---|---|

| Proper Charging Techniques | Follow recommended charging profiles |

| Routine Maintenance | Conduct visual inspections and capacity tests |

| Use Quality Components | Utilize manufacturer-recommended chargers |

How Can Proper Charging Techniques Enhance Safety?

Proper charging techniques are critical in preventing overheating and potential battery failure. Users should avoid overcharging by using chargers specifically designed for their battery type and adhering to recommended charging times.Charging Guidelines Chart:

Wholesale lithium golf cart batteries with 10-year life? Check here.

| Guideline | Recommendation |

|---|---|

| Charge Rate | Use appropriate charge rates as per specifications |

| Charging Duration | Avoid overnight charging; monitor charge completion |

What Role Does a Battery Management System (BMS) Play?

A BMS is essential for monitoring battery health, managing charge cycles, and ensuring safe operation by preventing overcharging, deep discharging, and thermal runaway.BMS Functions Chart:

| Function | Description |

|---|---|

| Voltage Monitoring | Ensures cells remain within safe voltage limits |

| Temperature Control | Monitors heat levels to prevent overheating |

Know More:

Want OEM lithium forklift batteries at wholesale prices? Check here.

What Safety Features Are Integrated into Modern LiFePO4 Batteries?

How Can Users Mitigate Risks Associated with Battery Failure or Overheating?

Why Is It Important to Have a Reliable Battery Management System (BMS) in Place?

How Important Is Adequate Ventilation for Battery Safety?

Adequate ventilation is crucial for dissipating heat generated during charging and discharging processes. Users should install batteries in well-ventilated areas to minimize the risk of overheating.Ventilation Impact Chart:

| Ventilation Type | Effect on Temperature |

|---|---|

| Poor Ventilation | Increased risk of overheating |

| Good Ventilation | Maintains optimal operating temperatures |

What Are Effective Cooling Strategies for High-Performance Applications?

For applications that demand high performance, incorporating active cooling systems such as fans or liquid cooling can significantly reduce the risk of thermal issues.Cooling Strategies Chart:

| Strategy | Description |

|---|---|

| Active Cooling | Use fans or liquid cooling systems |

| Heat Sinks | Install heat sinks to dissipate excess heat |

How Can Regular Monitoring Help Prevent Overheating?

Regular monitoring involves checking temperature levels, charge status, and overall battery health through sensors or manual checks. This proactive approach allows users to identify potential issues before they escalate.Monitoring Techniques Chart:

| Technique | Description |

|---|---|

| Temperature Sensors | Install sensors linked to a BMS |

| Manual Checks | Periodically inspect batteries for signs of wear |

What Are the Best Practices for Long-Term Battery Storage?

When storing batteries long-term, it is essential to keep them in a cool, dry place away from direct sunlight or extreme temperatures to prevent degradation.Storage Guidelines Chart:

| Practice | Recommendation |

|---|---|

| Ideal Temperature | Store between 0°C (32°F) and 25°C (77°F) |

| Charge Level | Store at around 50% charge |

How Do Environmental Factors Affect Battery Safety?

Environmental factors such as temperature extremes, humidity, and exposure to corrosive substances can significantly impact battery performance and safety. Users should be mindful of these factors when installing or storing batteries.Environmental Impact Chart:

| Factor | Effect on Battery |

|---|---|

| High Temperatures | Increases risk of thermal runaway |

| Humidity | Can lead to corrosion |

Conclusion

Mitigating risks associated with battery failure or overheating requires a multi-faceted approach that includes proper charging techniques, effective monitoring systems, adequate ventilation, and adherence to best practices for storage. By implementing these strategies, users can enhance the safety and longevity of their lithium-ion batteries.

Expert Views

“Understanding how to mitigate risks associated with battery failure is crucial in today’s energy-dependent world,” states an expert from Redway Tech. “By adopting proactive measures such as using a BMS and ensuring proper ventilation, users can significantly reduce the likelihood of overheating incidents.”

FAQ Section

- What are some key preventive measures against battery failure?

Key measures include following proper charging techniques, utilizing a BMS, ensuring good ventilation, and conducting regular maintenance checks. - How does temperature affect battery safety?

Extreme temperatures can increase the risk of thermal runaway; maintaining an optimal temperature range is essential for safe operation. - What should I do if my battery overheats?

Immediately disconnect it from power sources, allow it to cool in a well-ventilated area, and inspect it for damage before further use.