Built-in Battery Management Systems (BMS) are crucial for protecting LiFePO4 batteries by monitoring voltage, current, and temperature to prevent conditions that could lead to damage or safety hazards. They provide essential features like overcharge and over-discharge protection, ensuring optimal performance and longevity.

What is a Battery Management System?

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery by monitoring its state, calculating its data, reporting that information, controlling its environment, and balancing its cells. In LiFePO4 batteries, the BMS plays a vital role in maintaining safety and performance.

How Does a BMS Protect Against Overcharging?

Overcharging can lead to overheating and potential thermal runaway in lithium batteries. A BMS protects against overcharging by monitoring the voltage of each cell and disconnecting the charger when it reaches the maximum safe voltage level (typically around 3.65V for LiFePO4). This prevents damage and ensures safe operation.

Wholesale lithium golf cart batteries with 10-year life? Check here.

How Does a BMS Prevent Over-Discharging?

Over-discharging can permanently damage lithium-ion cells by pushing them below their minimum voltage threshold (around 2.5V for LiFePO4). The BMS monitors cell voltages during discharge and disconnects the load if any cell drops below this threshold, thus protecting the battery from irreversible damage.

How Does Cell Balancing Work in a BMS?

Cell balancing ensures that all cells within the battery pack maintain equal voltage levels during charging and discharging. The BMS redistributes charge among cells to prevent one cell from becoming overcharged while others remain undercharged, which optimizes performance and extends battery lifespan.

Want OEM lithium forklift batteries at wholesale prices? Check here.

Know More:

What Safety Features Do LiFePO4 Golf Cart Batteries Offer?

How Do Built-in Battery Management Systems (BMS) Protect LiFePO4 Batteries?

What Temperature Ranges Are Safe for LiFePO4 Golf Cart Battery Operation?

How Do LiFePO4 Batteries Perform in Extreme Weather Conditions?

What Are the Risks of Not Having a BMS?

Without a BMS, LiFePO4 batteries are vulnerable to several risks:

- Overcharging: Can cause overheating or fire.

- Over-discharging: Leads to permanent damage.

- Cell Imbalance: Results in reduced capacity and lifespan.

- Temperature Extremes: Increases risk of thermal runaway.

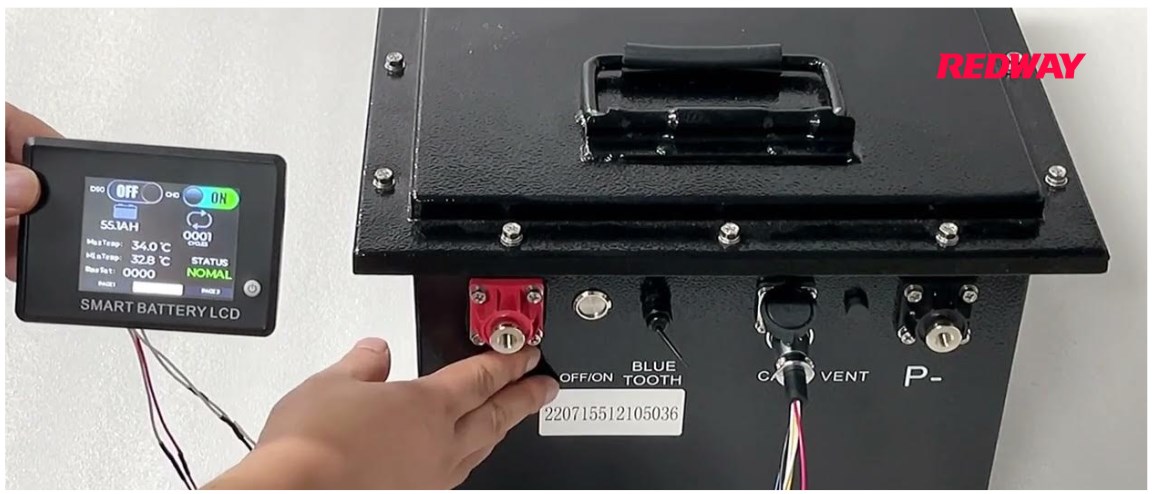

How Can Users Monitor BMS Performance?

Users can monitor BMS performance through built-in indicators or external monitoring systems that display key metrics such as voltage levels, current flow, temperature readings, and state of charge (SoC). Regular checks ensure that the battery operates within safe parameters.Expert Views:

“Integrating a robust Battery Management System is essential for maximizing the safety and efficiency of LiFePO4 batteries,” states an expert from Redway. “By preventing overcharging and over-discharging while ensuring cell balance, users can significantly extend battery life and enhance performance.”

Conclusion

Built-in Battery Management Systems are critical for protecting LiFePO4 batteries from various risks associated with improper usage. By providing essential safety features such as overcharge protection, over-discharge prevention, and cell balancing, a well-functioning BMS ensures optimal performance and longevity of lithium batteries.

FAQ Section

- What does a Battery Management System do?

A Battery Management System monitors battery state, controls charging/discharging processes, balances cells, and ensures safety. - Why is overcharge protection important?

Overcharge protection prevents overheating and potential thermal runaway, which can lead to fires or battery failure. - How often should I check my battery management system?

Regular checks should be performed every few months or whenever you notice unusual behavior from your battery system.