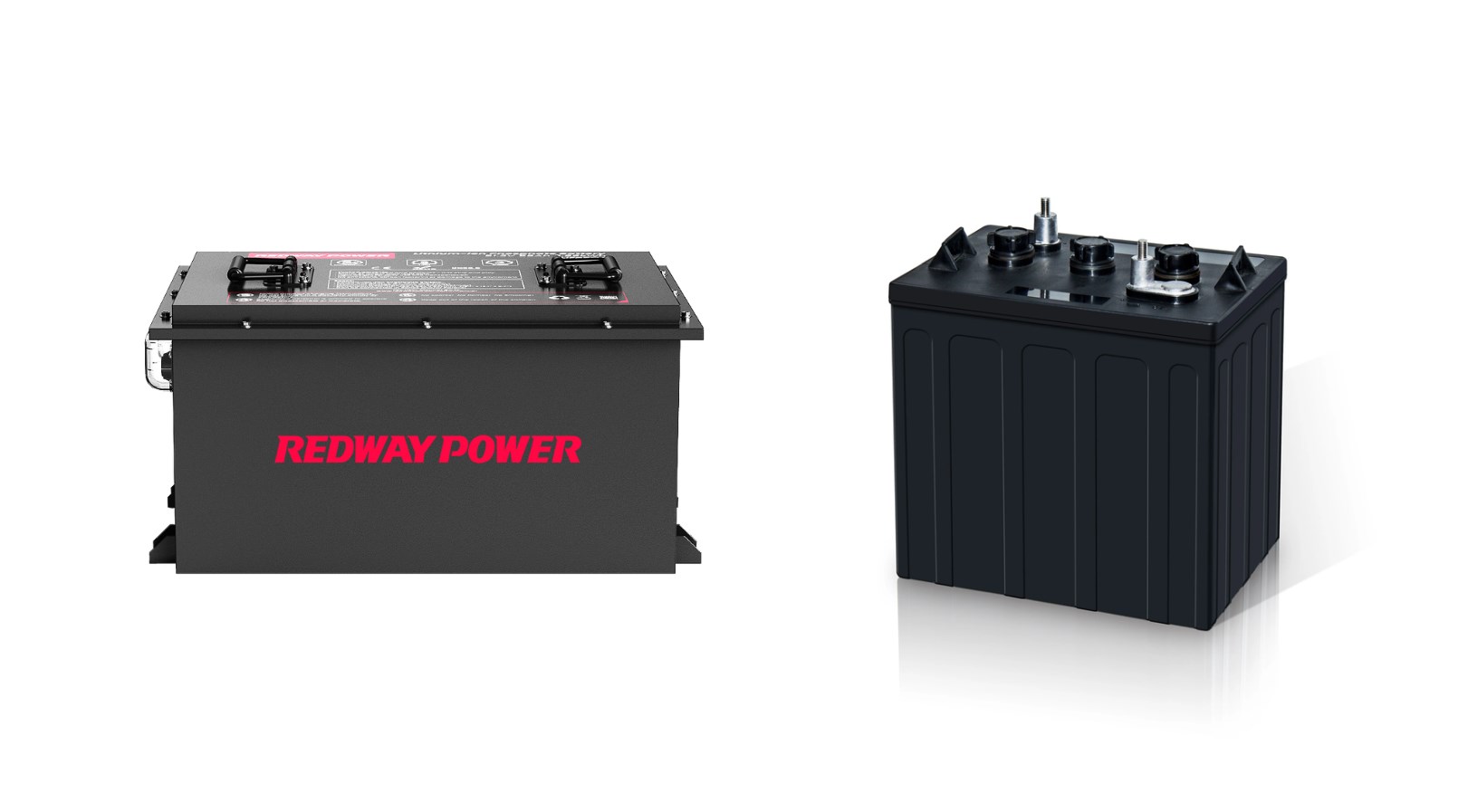

Lithium iron phosphate (LiFePO4) batteries are a type of rechargeable lithium-ion battery that uses lithium iron phosphate as the cathode material. Known for their safety, stability, and long lifespan, these batteries are increasingly popular in applications such as golf carts due to their efficiency and lower environmental impact compared to traditional lead-acid batteries.

What Materials Can Be Recycled from LiFePO4 Batteries?

Materials that can be recycled from LiFePO4 batteries include lithium, iron, and phosphate. Additionally, components like aluminum and copper can also be recovered during the recycling process.

The key materials that can be recycled from LiFePO4 batteries include:

Wholesale lithium golf cart batteries with 10-year life? Check here.

- Lithium: Essential for battery production and can be reused.

- Iron: A primary component that can be extracted and repurposed.

- Phosphate: Can be recovered for use in fertilizers or other applications.

What Is the Recycling Process for LiFePO4 Batteries?

The recycling process for LiFePO4 batteries involves several steps: first, the batteries are dismantled to separate components. Then, physical methods like shredding and sieving are used, followed by chemical processes to extract valuable metals for reuse.

The recycling process typically involves several steps:

Want OEM lithium forklift batteries at wholesale prices? Check here.

- Collection: Used batteries are gathered from consumers or retailers.

- Sorting: They are sorted based on chemistry to ensure proper processing.

- Dismantling: The batteries are disassembled to separate valuable components.

- Material Recovery: Techniques such as hydrometallurgical or pyrometallurgical processes extract lithium, iron, and phosphorus for reuse.

What Are the Environmental Benefits of Recycling LiFePO4 Batteries?

Recycling LiFePO4 batteries helps conserve natural resources by recovering valuable materials and reducing the need for mining. It also minimizes environmental pollution and waste, contributing to a more sustainable battery lifecycle.

Recycling offers significant environmental benefits:

- Reduction of Landfill Waste: By recycling, we can significantly reduce landfill contributions.

- Conservation of Resources: It decreases the need for raw material extraction, minimizing ecological disruption.

- Lower Carbon Footprint: The recycling process generally has a smaller carbon footprint compared to mining new materials.

How Do LiFePO4 Batteries Compare to Lead-Acid Batteries in Terms of Recycling?

LiFePO4 batteries have higher recycling rates than lead-acid batteries, which typically recycle around 70-80% of their materials. Additionally, lead-acid recycling poses more environmental risks due to toxic lead contamination during disposal processes.

Know More:

How Recyclable Are LiFePO4 Golf Cart Batteries?

How Do LiFePO4 Batteries Contribute to Sustainable Golfing Practices?

What Environmental Impact Do LiFePO4 Golf Cart Batteries Have?

What is the Carbon Footprint of LiFePO4 Batteries Compared to Lead-Acid?

What Are the Challenges in Recycling LiFePO4 Batteries?

Challenges in recycling LiFePO4 batteries include the complexity of their materials and the need for advanced technology to separate and recover components efficiently. The initial investment in recycling facilities can also be high.

- Complexity of Dismantling: The need for advanced technology to separate various components efficiently.

- Cost Factors: High initial investment required for establishing effective recycling facilities.

- Market Demand Fluctuations: Variability in demand for recycled materials can affect profitability.

What Regulations Govern the Recycling of LiFePO4 Batteries?

Regulations governing the recycling of LiFePO4 batteries vary by region but generally focus on environmental protection and safe disposal practices. Compliance with local laws is essential for proper battery recycling.

What Are the Economic Implications of Recycling LiFePO4 Batteries?

Recycling LiFePO4 batteries can have positive economic implications by creating jobs in the recycling sector and reducing costs associated with raw material extraction. It also supports a circular economy by reusing materials.

How Can Consumers Properly Dispose of LiFePO4 Batteries?

Consumers should dispose of LiFePO4 batteries at designated recycling centers or collection points rather than throwing them in regular trash. Many retailers also offer battery take-back programs for safe disposal.

- Use authorized collection points or battery retailers that offer recycling services.

- Participate in local recycling programs aimed at responsible battery disposal.

- Avoid throwing used batteries in regular trash due to potential environmental hazards.

What Innovations Are Emerging in Battery Recycling Technology?

Emerging innovations in battery recycling technology include new methods that use less energy and fewer harmful chemicals, such as water-based processes that recover lithium efficiently while minimizing environmental impact.

- New methods that enhance material recovery rates while reducing environmental impact.

- Development of processes that utilize less harmful chemicals or energy-intensive methods.

- Research focused on improving efficiency and cost-effectiveness in battery recycling operations.

Expert Views

“Recycling is not just an option; it’s a necessity for sustainable battery use,” states an expert from Redway. “LiFePO4’s high recyclability positions it as a leader in eco-friendly energy solutions.”

Conclusion

In summary, lithium iron phosphate (LiFePO4) golf cart batteries offer significant recyclability advantages over traditional battery types, contributing positively to environmental sustainability while providing valuable resources for reuse. Understanding these aspects encourages responsible consumption and promotes a circular economy within battery technology.

FAQ Section

- How recyclable are LiFePO4 batteries?

They have a high recyclability rate exceeding 90%, allowing most materials to be recovered and reused. - What materials can be recycled from these batteries?

Key recyclable materials include lithium, iron, and phosphate. - What regulations exist regarding battery recycling?

Various regulations like the EU’s Battery Directive ensure safe disposal and promote sustainable practices within the industry.