Accessing the battery on a Toyota forklift involves several steps to ensure safety and efficiency. First, turn off the forklift and remove the key. Next, locate the battery compartment, which is typically found under the seat or at the rear of the forklift. Finally, remove any covers or panels to expose the battery for inspection or maintenance.

Steps to Access the Battery on a Toyota Forklift

To access the battery on a Toyota forklift, first, turn off the forklift and remove the ignition key. Locate the battery compartment, typically under the operator’s seat or at the rear. Finally, remove any covers or panels to expose the battery for inspection or maintenance.

1. Safety First

Wholesale lithium golf cart batteries with 10-year life? Check here.

Before accessing the battery, ensure that you follow all safety protocols:

- Turn off the forklift.

- Remove the ignition key.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

| Safety Measure | Description |

|---|---|

| Turn Off Forklift | Prevents accidental operation |

| Remove Key | Ensures no power is supplied |

| Wear PPE | Protects against battery acid exposure |

2. Locate the Battery Compartment

Want OEM lithium forklift batteries at wholesale prices? Check here.

The battery compartment on a Toyota forklift is usually located:

- Under the operator’s seat.

- At the rear of the forklift.

Refer to your specific model’s manual for precise locations.

| Forklift Model | Battery Location |

|---|---|

| Toyota 7FBE | Under operator’s seat |

| Toyota 8FGCU | Rear compartment |

3. Remove Covers or Panels

Once you have located the battery compartment:

- Remove any covers or panels that obstruct access.

- Use appropriate tools, such as a screwdriver or wrench, if necessary.

| Tool Required | Purpose |

|---|---|

| Screwdriver | To remove screws |

| Wrench | To loosen bolts |

4. Inspect the Battery

After gaining access:

- Check for any signs of damage or corrosion.

- Ensure that terminals are clean and securely connected.

| Inspection Aspect | What to Look For |

|---|---|

| Corrosion | Greenish or white residue on terminals |

| Damage | Cracks or leaks in battery casing |

5. Reassemble and Test

Once maintenance is complete:

- Replace any covers or panels securely.

- Reinsert the ignition key and perform a test run to ensure everything is functioning properly.

| Action | Description |

|---|---|

| Replace Covers | Ensures safety during operation |

| Test Run | Confirms proper functionality |

What Safety Protocols Should Be Followed?

When handling forklift batteries, always wear appropriate personal protective equipment (PPE) such as gloves and safety goggles. Ensure the area is well-ventilated and free of open flames. Use proper lifting equipment for battery changes, and have emergency wash stations nearby in case of spills. Regularly inspect charging equipment for safety compliance.

Before attempting any maintenance, it’s essential to follow safety protocols:

- Turn off the forklift completely.

- Remove the ignition key to prevent accidental operation.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

| Safety Measure | Description |

|---|---|

| Turn Off Forklift | Prevents accidental operation |

| Remove Key | Ensures no power is supplied |

| Wear PPE | Protects against battery acid exposure |

Where is the Battery Compartment Located?

The battery compartment in most Toyota forklifts is usually found under the operator’s seat or at the rear of the unit. For precise locations, refer to your specific model’s manual, as configurations may vary by model.

| Forklift Model | Battery Location |

|---|---|

| Toyota 7FBE | Under operator’s seat |

| Toyota 8FGCU | Rear compartment |

How to Remove Covers or Panels Safely?

To safely remove covers or panels on a forklift, ensure the power is turned off and the brakes are engaged. Use the proper tools to avoid damaging components, and wear PPE to protect against sharp edges or accidental contact with electrical parts.

Once you have located the battery compartment, follow these steps:

- Remove any covers or panels obstructing access.

- Use appropriate tools, such as screwdrivers or wrenches, if necessary.

| Tool Required | Purpose |

|---|---|

| Screwdriver | To remove screws |

| Wrench | To loosen bolts |

What Steps Should Be Taken to Inspect the Battery?

Inspect the forklift battery by checking for corrosion on terminals, ensuring cables are undamaged, and measuring electrolyte levels with a hydrometer. Clean the battery case regularly and verify that vent caps are in good condition to prevent leaks or buildup.

After gaining access, inspect the battery for:

- Signs of damage or corrosion.

- Ensure terminals are clean and securely connected.

Regular inspections can prevent unexpected failures and prolong battery life.

How to Properly Charge a Forklift Battery?

Charge the forklift battery when it drops to about 20% capacity, ensuring it’s done in a well-ventilated area. Use the correct charger and follow manufacturer instructions. Avoid overcharging; always check water levels after charging and clean any corrosion from terminals.

Charging your forklift battery correctly is vital for its longevity:

- Only recharge if it has been discharged by 30% or more.

- Avoid running it below 20% capacity.

- Allow time for cooling after charging.

What Are Common Signs of a Failing Forklift Battery?

Common signs of a failing forklift battery include reduced lifting power, longer charging times, swelling or leakage from the battery case, and unusual smells or sounds during operation. Regular inspections can help identify these issues early.

Recognizing signs of battery failure can save time and resources:

- Reduced lifting capacity.

- Slow response times when operating.

- Visible corrosion around terminals.

How to Dispose of Forklift Batteries Safely?

Dispose of forklift batteries by following local regulations for hazardous waste. Contact a certified recycling facility that specializes in battery disposal. Never throw batteries in regular trash; ensure they are stored safely until they can be properly recycled or disposed of.

Proper disposal of forklift batteries is crucial due to environmental regulations:

- Follow local guidelines for hazardous waste disposal.

- Partner with certified recycling facilities that specialize in battery disposal.

Know More:

Where Can I Find Reliable Sources and Sales for Forklift Batteries?

Where Can You Buy Forklift Batteries Near Me?

Where Can You Find Forklift Batteries for Sale Near Me?

Where Can I Purchase a Reliable Forklift Battery?

Where Can I Find Affordable Options for Forklift Batteries?

How Can Forklift Batteries Be Used in Solar Systems?

Related Subject: Forklift Batteries

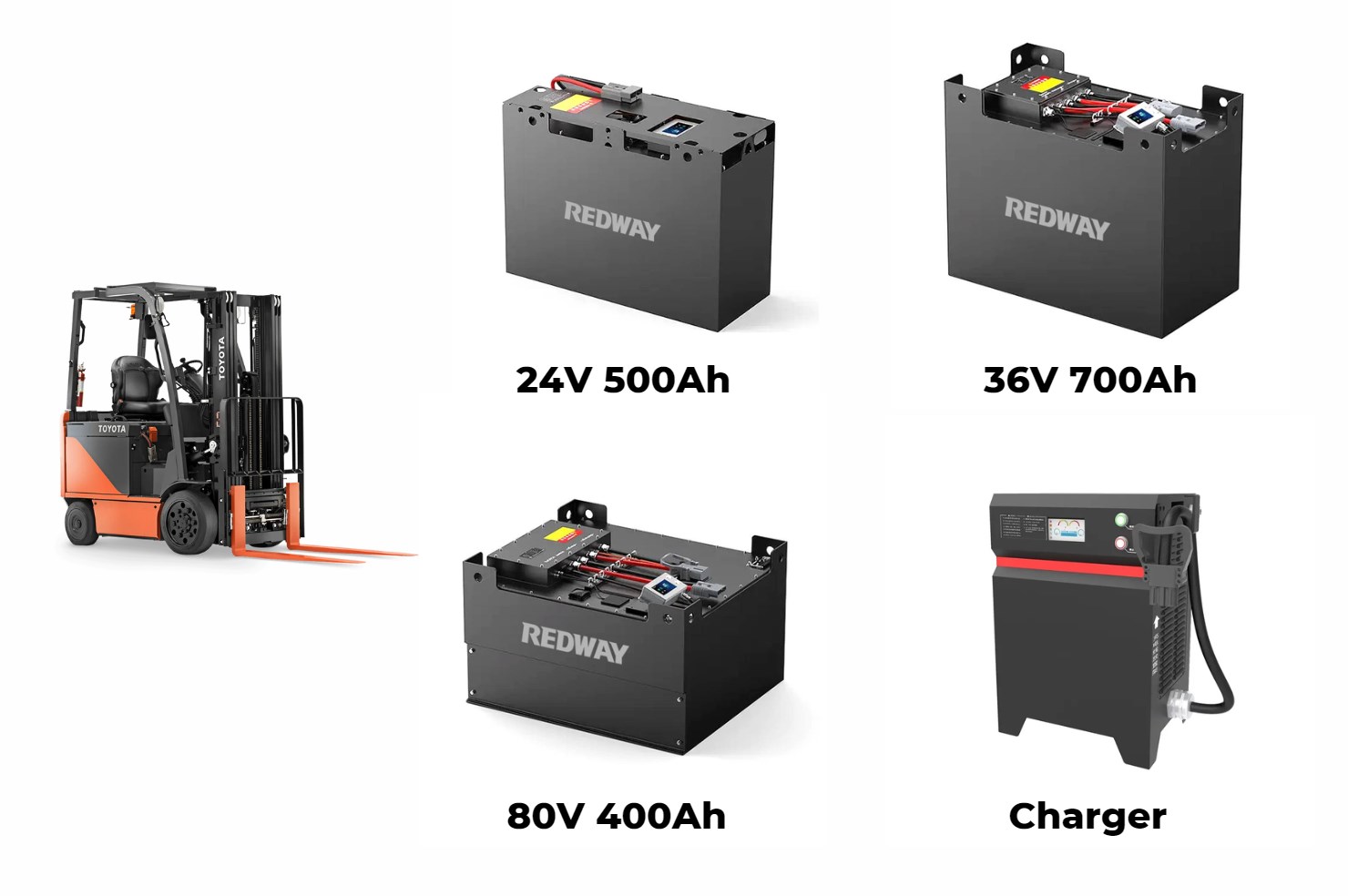

The relationship between accessing forklift batteries and maintaining optimal performance is crucial. Regular maintenance ensures that batteries operate efficiently, which directly impacts the overall productivity of forklifts. Redway Battery specializes in manufacturing high-quality lithium LiFePO4 forklift batteries designed for durability and performance.

Top Competitors in the Forklift Battery Market 2025

In 2025, leading competitors in the forklift battery market include companies like Redway Battery, Crown Battery Manufacturing Company, and EnerSys. These companies are recognized for their innovative solutions and commitment to sustainability in material handling operations.

Here are some notable competitors in the battery market that also offer options compatible with various applications:

| Competitor Name | Lithium Battery Options Available |

|---|---|

| Redway Battery | Yes |

| A123 Systems | Yes |

| LG Chem | Yes |

| Panasonic | Yes |

| BYD | Yes |

In conclusion, accessing and maintaining the battery on a Toyota forklift is essential for ensuring optimal performance and longevity. By following proper procedures and utilizing high-quality batteries like those from Redway Battery, operators can enhance their equipment’s reliability and efficiency.

Latest News

- Battery Maintenance Innovations: Recent advancements in battery maintenance technology are enhancing the efficiency of forklift operations, leading to longer battery life and reduced downtime.

- Sustainability Initiatives: Many companies are adopting eco-friendly practices in battery disposal and recycling, aligning with global sustainability goals.

- Market Trends: The demand for electric forklifts is increasing, driving innovations in battery technology and management systems.

Redway Expert Comment

“At Redway Battery, we understand the importance of proper battery access and maintenance in forklifts. Regular inspection and maintenance of forklift batteries can significantly enhance performance and extend lifespan. Our expertise in lithium LiFePO4 batteries ensures that we provide solutions that not only meet but exceed industry standards for reliability and efficiency.”

When considering a Toyota electric pallet jack battery replacement, it’s crucial to select the right type of battery for optimal performance. A high-quality Toyota electric pallet jack battery replacement will improve efficiency and reduce maintenance costs. Many businesses turn to specialized solutions when looking for a Toyota electric pallet jack battery replacement, as it ensures reliable operation throughout the day. Lithium batteries, for example, offer a longer lifespan and faster charging times. For those in need of a reliable source, Redway Battery, China LiFePO4 Battery Wholesale Supplier, offers high-performance lithium solutions tailored for industrial equipment, including pallet jacks. If you’re searching for the best Toyota electric pallet jack battery replacement, choosing a lithium option from Redway Battery, China LiFePO4 Battery Wholesale Supplier can provide the power and durability your business requires.

Open TOYOTA forklift engine hood

FAQs

How do you get to the battery on a forklift?

To access the battery on a forklift, first ensure the forklift is powered off and safely parked. Remove any covers or panels securing the battery compartment, which may involve unscrewing bolts or releasing latches. Carefully lift out the battery or slide it out of the compartment, depending on the forklift model.

How to jump start a Toyota forklift?

To jump start a Toyota forklift, park a functioning vehicle nearby and connect jumper cables. Attach the positive (+) cable to the positive terminal of the forklift battery and the other end to the positive terminal of the donor battery. Connect the negative (-) cable to the negative terminal of the donor battery, then attach the other end to a metal ground on the forklift. Start the donor vehicle and let it charge the forklift battery for a few minutes.

How to check the battery of a forklift?

To check a forklift battery, first ensure it’s disconnected. Use a multimeter to measure the voltage across the battery terminals. A fully charged battery typically shows around 12.6 to 12.8 volts for lead-acid types. Inspect for any signs of corrosion, leaks, or swelling, and check the fluid levels if applicable.

How do you move a forklift with a dead battery?

To move a forklift with a dead battery, you can manually push it if it’s a smaller model, ensuring the parking brake is released. For larger models, use a tow truck or forklift towing equipment, adhering to the manufacturer’s guidelines for safe towing. Always consult the operator’s manual for specific instructions related to your forklift model.

How do you maintain a Toyota forklift battery?

To maintain a Toyota forklift battery, check electrolyte levels regularly (for lead-acid), clean terminals, and inspect for corrosion. Charge the battery fully after each shift, keep it at room temperature, and use distilled water to top off cells. For lithium batteries, monitor software alerts and maintain proper charging cycles.

Where is the battery on a Toyota forklift?

The battery on a Toyota forklift is typically located beneath the operator seat or under a rear battery cover. For electric models, lift the seat or rear panel to access the battery compartment. Always turn off the forklift before accessing or servicing the battery area.

How to check the battery of a forklift?

To check a forklift battery, use a voltmeter to measure voltage and inspect electrolyte levels (for lead-acid). Look for corrosion, swelling, or leaks, and confirm that the battery charges fully after a shift. Routine checks help extend battery life and performance.

How to maintain a Toyota car battery?

To maintain a Toyota car battery, keep terminals clean and tight, check for corrosion, and ensure the charging system functions correctly. Test voltage regularly and drive often to prevent drain. If it’s a maintenance-required battery, inspect fluid levels and top off with distilled water as needed.

How to access battery on Toyota forklift?

To access the battery on a Toyota forklift, first turn off the unit. Then, lift the operator seat or remove the rear battery compartment cover, depending on the model. Use proper lifting tools if the battery is heavy, and wear safety gloves and eyewear.

Where is battery located in Toyota forklift?

The battery in a Toyota forklift is typically located in the rear compartment or beneath the operator seat. In electric forklifts, it may sit in a removable battery tray, accessed by lifting the seat or a hinged lid behind the driver position.

Where is hood latch on Toyota forklift?

The hood latch on a Toyota forklift is usually found at the base of the operator seat or on the side panel of the forklift body. Pull or lift the latch handle to open the battery compartment or engine cover, depending on the forklift type.

Where to find forklift battery maintenance PDF?

You can find a forklift battery maintenance PDF on manufacturer websites, such as Toyota Material Handling, or by searching “Toyota forklift battery maintenance PDF.” These guides cover inspection, watering, charging tips, and safety procedures. Dealer service portals may also offer free downloads.

Know more:

toyota forklift battery location

toyota forklift battery access

toyota forklift battery