Replacing forklift battery cells requires careful preparation, knowledge of safety protocols, and an understanding of the replacement process. By following these guidelines, operators can ensure a successful replacement that enhances forklift performance.

What Are Forklift Battery Cells and Their Functions?

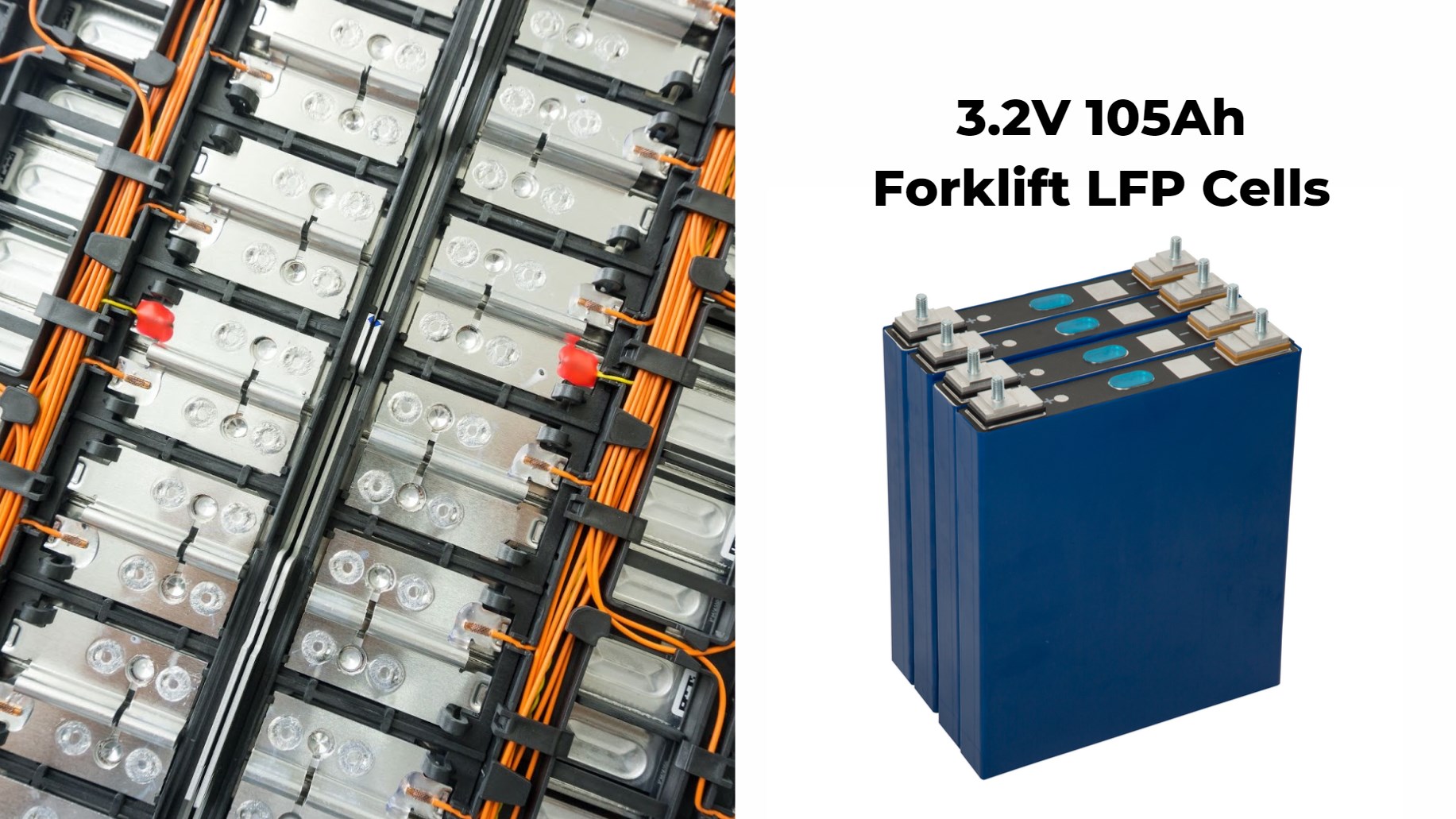

Forklift battery cells are individual units within a battery pack that store electrical energy, contributing to the overall voltage and capacity required to power a forklift. Understanding their function is crucial for effective replacement.Chart: Overview of Forklift Battery Cell Types

| Type | Description | Advantages |

|---|---|---|

| Lead-Acid | Traditional battery type | Cost-effective, durable |

| Lithium-Ion | Modern technology | Longer lifespan, faster charging |

How Should You Prepare for Replacement of Forklift Battery Cells?

Preparation is key when replacing forklift battery cells. Begin by wearing appropriate personal protective equipment (PPE) such as gloves and goggles. Ensure that you have all necessary tools on hand, including wrenches, screwdrivers, and a multimeter.Chart: Preparation Checklist for Cell Replacement

Wholesale lithium golf cart batteries with 10-year life? Check here.

| Item | Importance |

|---|---|

| Personal Protective Equipment (PPE) | Protects against hazards |

| Tools | Ensures efficient replacement |

| Compatible Replacement Cells | Guarantees proper fit |

What Are the Steps Involved in Replacing Forklift Battery Cells?

Replacing forklift battery cells involves several steps:

- Disconnect Power: Ensure that power is turned off before beginning.

- Remove Old Cells: Carefully disconnect cables (negative first) and remove old cells.

- Inspect Compartment: Check for corrosion or damage in the battery compartment.

- Install New Cells: Place new cells securely in their designated spots.

- Reconnect Cables: Attach cables (positive first) and ensure all connections are tight.

- Test New Installation: Use a multimeter to check voltage levels.

Chart: Step-by-Step Process for Cell Replacement

Want OEM lithium forklift batteries at wholesale prices? Check here.

| Step | Action |

|---|---|

| 1 | Disconnect power |

| 2 | Remove old cells |

| 3 | Inspect compartment |

| 4 | Install new cells |

| 5 | Reconnect cables |

| 6 | Test installation |

What Maintenance Tips Should You Follow After Replacing Cells?

Post-replacement maintenance is essential for optimal performance:

- Regularly monitor fluid levels in lead-acid batteries.

- For lithium-ion batteries, check charge status frequently.

- Clean terminals regularly to prevent corrosion.

How Do Environmental Regulations Impact Battery Disposal?

Environmental regulations dictate how batteries must be disposed of or recycled after replacement. Compliance with these regulations is crucial for minimizing environmental impact and ensuring safety during disposal.

Know More:

How to Replace Forklift Battery Cells?

What Are the Different Sizes of Forklift Battery Cells?

How to Safely Remove a Forklift Battery Cell?

Can You Safely Charge a 36 Volt Forklift Battery with 12 Volts?

What Tools Are Necessary for Replacing Forklift Battery Cells?

Essential tools include:

- Wrenches

- Screwdrivers

- Multimeter

- Torque wrench

Having these tools ready will streamline the replacement process.

How Can You Ensure Safety During the Replacement Process?

To ensure safety:

- Always wear PPE.

- Disconnect power before beginning work.

- Follow proper procedures for handling battery terminals.

Conclusion

Replacing forklift battery cells is a critical task that requires careful preparation, adherence to safety protocols, and thorough knowledge of the process involved. By following these guidelines, operators can enhance their forklifts’ performance while ensuring their safety during replacement.

Expert Views

“Properly replacing forklift battery cells not only extends the life of your equipment but also ensures safety in operations,” says an expert from Redway. “Understanding each step in this process can significantly reduce risks associated with battery maintenance.”

FAQ Section

- What are common signs that forklift battery cells need replacement?

Common signs include reduced runtime, slow charging times, or visible damage such as swelling or leaks. - How often should forklift battery cells be replaced?

The frequency of replacement depends on usage patterns but typically ranges from every 3-5 years for lead-acid batteries. - Can I replace individual cells instead of the entire battery?

Yes, individual cell replacement is possible if they are compatible with existing cells; however, it’s essential to ensure uniformity in performance.