Wiring batteries in parallel increases capacity while keeping voltage constant, and wiring in series boosts voltage while maintaining capacity. Choosing the right wiring method depends on your power needs, device specifications, and battery type to optimize energy output and lifespan.

What Is the Difference Between Wiring Batteries in Series and Parallel?

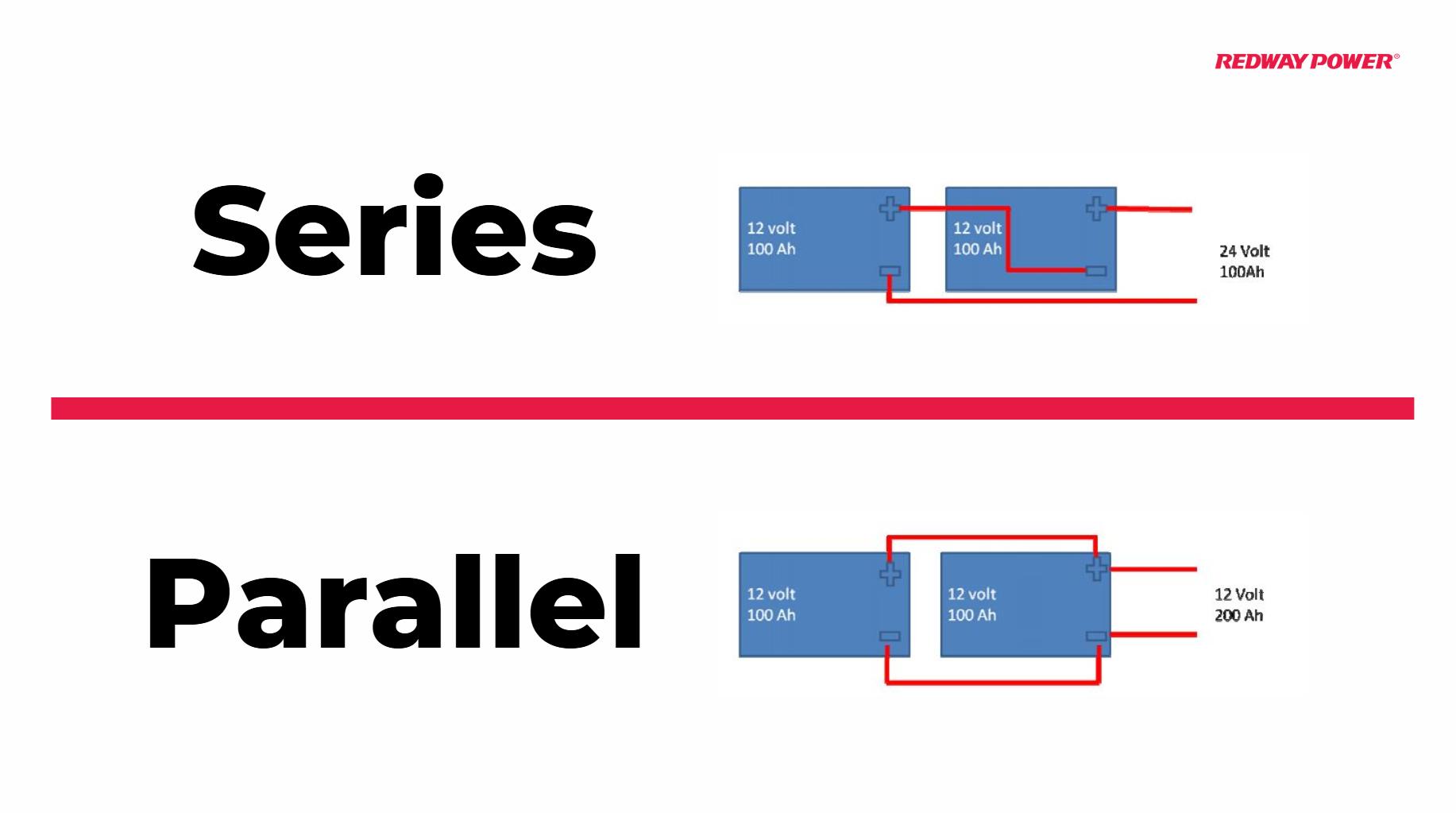

Wiring in series connects the positive terminal of one battery to the negative of another, increasing voltage; parallel wiring connects positive to positive and negative to negative, increasing amp hours.

In a series arrangement, voltages add up while capacity (Ah) remains the same. This is essential for devices requiring higher operating voltage. Parallel wiring keeps voltage constant but multiplies capacity, extending runtime. Understanding these fundamental differences helps users tailor battery configurations to specific applications, maximizing efficiency and device compatibility.

Wholesale lithium golf cart batteries with 10-year life? Check here.

How Do I Safely Wire Batteries in Series?

Connect the positive terminal of the first battery to the negative terminal of the second; overall voltage is the sum of all batteries’ voltages.

Ensure all batteries are of the same voltage and capacity to prevent imbalance issues that can shorten battery life or cause damage. Use appropriate gauge wiring rated for the total voltage and current. Double-check polarity before finalizing connections to avoid short circuits. Install fuses or circuit breakers for added safety and consult manufacturer guidelines, such as from Redway Battery, for precise wiring instructions.

Want OEM lithium forklift batteries at wholesale prices? Check here.

How Do I Wire Batteries in Parallel Correctly?

Connect all battery positive terminals together and all negatives together, maintaining the same voltage but increasing capacity.

Use equal-length cables and identical battery types to minimize resistance differences that might cause uneven charging or discharging. Parallel wiring is ideal for applications needing longer runtime without increasing voltage, such as solar energy storage or golf carts. Implement proper circuit protection and monitor battery health regularly to prevent issues like overcharging or imbalance.

Which Applications Require Series Wiring Versus Parallel Wiring?

Series wiring suits devices requiring higher voltage, whereas parallel wiring suits longer runtimes at a fixed voltage.

Electric vehicles, power tools, and some solar inverters often require increased voltage, making series connections preferable. In contrast, deep cycle battery banks for renewable energy or backup power use parallel wiring to extend operational hours. Some complex systems combine both series and parallel wiring to optimize voltage and capacity simultaneously.

Table 1: Series vs. Parallel Wiring Comparison

| Feature | Series Wiring | Parallel Wiring |

|---|---|---|

| Voltage Output | Sum of individual battery voltages | Same as single battery voltage |

| Capacity (Ah) | Same as single battery | Sum of individual battery capacities |

| Runtime | Same as single battery | Increased runtime |

| Application Examples | Power tools, electric vehicles | Solar storage, golf carts |

| Wiring Complexity | Moderate to high | Moderate |

Why Is Matching Battery Specifications Important in Series or Parallel Wiring?

Mismatched battery voltage, capacity, or age causes uneven discharge, reducing efficiency and risking damage.

Batteries wired together should be identical in chemistry, capacity (Ah), brand, and age to prevent imbalance. Dissimilar batteries create charge rate disparities, increasing wear and potential failure. Redway Battery ensures OEM-grade consistency in capacity and chemistry, making their LiFePO4 packs ideal for series/parallel configurations requiring reliability and safety.

How Do Battery Management Systems (BMS) Support Series and Parallel Configurations?

BMS monitors cell voltages, temperatures, and balances charging, protecting batteries from overcharge, over-discharge, and thermal events.

In series wiring, BMS equalizes voltage across cells preventing imbalance. In parallel setups, BMS controls current flow ensuring uniform discharge and recharge. Redway Battery integrates advanced BMS in their customized packs, improving pack longevity and safety, particularly in large or complex battery arrays.

When Should I Combine Series and Parallel Wiring?

Combine when needing both increased voltage and capacity in large battery banks.

For example, a 48V system requiring substantial capacity may wire four 12V batteries in series (to reach 48V), then multiple such series strings in parallel to boost capacity. Proper design and management are essential to avoid system instability. Consultation with manufacturers like Redway Battery offers guidance and tailored solutions for safe, efficient configurations.

How Do Environmental Factors Impact Wired Battery Systems?

Temperature, humidity, and vibration affect battery performance and wiring integrity.

Extreme temperatures can cause expansion or contraction of wiring and battery materials, leading to loose connections or damage. Moisture accelerates corrosion on terminals. Robust design and quality components from suppliers like Redway Battery minimize these risks through sealed cases and corrosion-resistant terminals. Regular inspection of wiring and connections is essential for long-term reliability.

Chart 1: Recommended Wiring Practices for Battery Systems

-

Use identical batteries for consistency

-

Employ proper cable gauge rated for current and voltage

-

Install circuit breakers or fuses for protection

-

Keep connections secure and corrosion-free

-

Integrate BMS for monitoring and balancing

How Does Redway Battery Support Customized Battery Wiring Solutions?

Redway Battery offers customized OEM/ODM battery packs with pre-configured series, parallel, or mixed wiring.

Their engineering team custom-designs battery layouts matched to application voltage and capacity needs, ensuring optimized pack size, efficient wiring paths, and integrated BMS units. This turnkey approach reduces installation errors, enhances safety, and meets stringent manufacturing and performance standards, helping clients from forklifts to solar systems implement reliable power solutions.

Redway Expert Views

“Proper wiring of batteries in series or parallel is crucial to harness energy efficiently and safely. At Redway Battery, our engineering expertise ensures modular, customizable battery solutions tailored to client-specific power requirements. Integrating high-quality LiFePO4 cells with smart BMS and optimal wiring prevents imbalance and extends pack life, critical for applications from golf carts to solar energy storage.” – Redway Battery Engineering Team

Conclusion

Wiring batteries in series or parallel allows flexible tailoring of voltage and capacity to meet diverse energy needs. Series wiring increases voltage while parallel wiring boosts capacity, and combining both supports complex power systems. Success relies on matching battery specifications, employing proper wiring techniques, and integrating management systems. Partnering with OEMs like Redway Battery ensures high-quality, custom solutions that optimize performance, safety, and longevity.

FAQs

1. Can I mix different battery types in series or parallel?

No, mixing types risks imbalance, faster degradation, and safety hazards.

2. How do I know what gauge wire to use for battery wiring?

Choose wire based on current rating and length; thicker gauges reduce voltage drop.

3. Is a battery management system necessary?

Highly recommended for multi-cell packs to monitor and protect batteries.

4. Can incorrectly wired batteries cause damage?

Yes, wrong polarity or improper wiring can cause short circuits or explosions.

5. Does Redway Battery provide pre-wired battery packs?

Yes, Redway offers customized, pre-wired OEM battery solutions with integrated BMS.