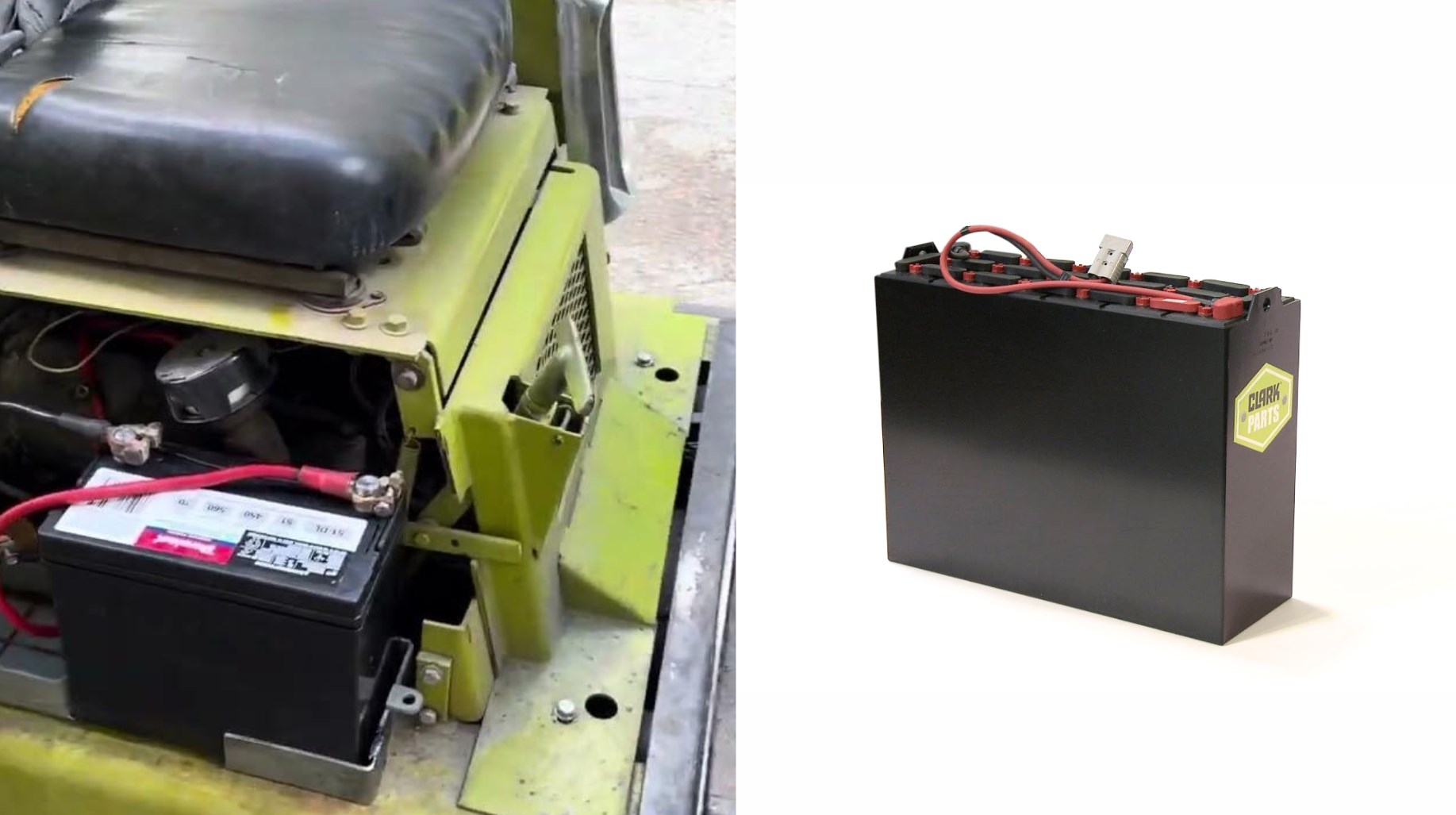

Proper maintenance of Clark C300 forklift batteries is crucial for ensuring optimal performance and extending battery life. Regular upkeep not only enhances safety but also prevents costly downtime and replacements, making it essential for efficient operations.

Proper maintenance for Clark C300 forklift batteries includes regular charging, watering, cleaning, and inspection. Following manufacturer guidelines for charging cycles and ensuring water levels are maintained are essential for optimal performance and longevity.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect battery terminals | Monthly | Prevent corrosion and ensure good connections |

| Clean battery case | Every 3 months | Remove dirt and prevent acid buildup |

| Check water levels | Weekly | Maintain electrolyte levels |

| Perform equalization charge | Monthly | Balance cell charge levels |

Key Benefits of Regular Maintenance

Key benefits of regular maintenance include prolonged battery lifespan, improved safety by preventing malfunctions, reduced operational costs due to fewer replacements, and consistent performance that enhances productivity in material handling operations.

Wholesale lithium golf cart batteries with 10-year life? Check here.

- Enhanced Performance: Well-maintained batteries deliver consistent power.

- Extended Lifespan: Following proper procedures can significantly prolong battery life.

- Improved Safety: Reduces risks associated with battery malfunctions or failures.

Know More:

What Are Forklift Battery Sizes and Configurations?

What Are the Key Features of 6 x 9 Forklift Batteries?

What Are Forklift Battery Amp Hours and Why Are They Important?

Why Is Proper Maintenance Important for Clark C300 Forklift Batteries?

What Is a Forklift Battery Charger Stand and Why Is It Important?

What Is a Forklift Battery Charger Station and Why Is It Important?

What Is a 36 Volt Single Phase Forklift Battery Charger?

Want OEM lithium forklift batteries at wholesale prices? Check here.

How Can I Properly Charge Clark C300 Forklift Batteries?

To properly charge Clark C300 forklift batteries, connect the charger to the battery after ensuring it’s cool. Follow the manufacturer’s recommended charging time and avoid overcharging to maintain battery health and efficiency.

Charging should be performed according to specific guidelines to avoid overcharging or undercharging:

- Charge After Use: Always recharge when the battery reaches 20-30% capacity.

- Allow Full Charge: Ensure the battery is charged fully before use.

- Avoid Partial Charges: This can reduce the total number of charge cycles available.

| Charging Do’s | Charging Don’ts |

|---|---|

| Charge when low | Overcharge |

| Use correct charger | Leave partially charged |

| Monitor voltage | Charge in extreme temps |

What Are the Key Maintenance Practices for Clark C300 Forklift Batteries?

Key maintenance practices include performing equalization charges, regularly checking and topping off water levels with distilled water, cleaning terminals to prevent corrosion, and inspecting for signs of wear or damage.

Effective maintenance practices include:

- Watering: Maintain proper water levels using distilled water to prevent damage.

- Cleaning: Regularly clean terminals and battery cases to prevent corrosion.

- Inspection: Conduct routine checks for signs of wear or damage.

How Does Battery Watering Affect Performance in Clark C300 Forklifts?

Proper battery watering is essential as it maintains electrolyte levels. Insufficient watering can lead to exposed plates, causing reduced capacity and overheating, while overwatering may result in acid spills and damage.

Watering is critical as it maintains electrolyte levels necessary for proper function:

- Frequency: Check water levels weekly; refill as needed.

- Method: Always add water after charging to avoid overflow.

Water Level Guidelines

| Water Level Indicator | Action Required |

|---|---|

| Below half an inch | Add distilled water |

| Overfilled | Drain excess carefully |

What Safety Precautions Should Be Taken During Maintenance?

Safety precautions include wearing protective gear such as gloves and goggles, ensuring proper ventilation when charging, using appropriate tools for maintenance tasks, and keeping a clean workspace to prevent accidents.

Safety is paramount when handling forklift batteries:

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation when charging lead-acid batteries.

- Avoid contact with battery acid; use neutralizing agents if spills occur.

How Can Battery Management Systems Improve Maintenance Efficiency?

Battery management systems enhance maintenance efficiency by providing real-time data on battery health, including voltage and water levels. They help schedule maintenance tasks proactively and reduce manual monitoring efforts.

Battery management systems provide real-time data on battery health, including:

- Voltage levels

- Temperature readings

- Water levels

These systems help streamline maintenance processes by alerting operators to potential issues before they escalate.

What Are the Consequences of Neglecting Clark C300 Forklift Battery Maintenance?

Neglecting maintenance can lead to reduced battery life, increased risk of equipment failure, safety hazards from acid spills or overheating, and higher operational costs due to frequent replacements or repairs.

Neglect can lead to severe consequences:

- Reduced efficiency and performance

- Increased risk of safety incidents

- Higher costs due to frequent replacements

What Are the Signs of a Failing Forklift Battery?

Signs of a failing forklift battery include difficulty holding a charge, reduced runtime, swelling or leakage from the battery casing, corrosion around terminals, or unusual odors indicating potential internal damage.

Common signs include:

- Decreased runtime

- Swelling or leaking cases

- Corroded terminals

Regular inspections can help identify these issues early.

How Often Should Clark C300 Forklift Batteries Be Inspected?

Clark C300 forklift batteries should be inspected regularly—ideally weekly or bi-weekly—depending on usage. Frequent checks help identify issues early and ensure optimal performance and safety during operation.

What Role Does Temperature Play in Battery Performance?

Temperature significantly affects battery performance; extreme heat can accelerate chemical reactions leading to faster degradation, while cold temperatures can reduce capacity. Maintaining an optimal temperature range is vital for efficient operation.

Temperature significantly affects battery efficiency:

- High temperatures can lead to overheating and reduced lifespan.

- Low temperatures can decrease capacity and performance.

Maintaining an optimal operating temperature range is essential for longevity.

Expert Views

“Proper maintenance of forklift batteries like those in the Clark C300 is not merely a recommendation; it’s a necessity that directly influences operational efficiency and safety,” states an expert from Redway.

Conclusion

Proper maintenance of Clark C300 forklift batteries is essential for ensuring optimal performance, enhancing safety, and extending equipment lifespan. By adhering to recommended practices such as regular inspections, appropriate charging routines, and diligent cleaning protocols, businesses can significantly improve their operational efficiency while minimizing costs associated with battery replacements.

FAQ Section

- What are common signs that a forklift battery needs maintenance?

Signs include decreased runtime, swelling or leaking cases, and corroded terminals. - How often should I check my forklift battery’s water level?

Water levels should be checked weekly, with refills done as necessary. - What safety measures should I take while maintaining forklift batteries?

Always wear protective gear, ensure good ventilation during charging, and avoid contact with acids. - How often should I clean my Clark C300 forklift’s battery?

It is recommended to clean the battery monthly to prevent build-up that could lead to corrosion. - What should I do if I notice corrosion on my battery terminals?

Clean the terminals immediately with a suitable cleaner and inspect for any damage; consider consulting a technician if necessary. - Can improper watering damage my forklift battery?

Yes, insufficient or excessive watering can lead to overheating or electrolyte spillage, damaging internal components.

Clark Forklift C300-50