Electric forklift batteries are essential power sources that enable electric forklifts to operate efficiently in various industrial settings. Over the past 12 years, Redway Battery has focused on manufacturing high-quality Lithium LiFePO4 batteries, including specialized solutions for electric forklifts. This article explores the components, benefits, and applications of electric forklift batteries, highlighting why they are crucial for modern material handling operations.

Electric forklift batteries are rechargeable power sources for electric forklifts. They typically come in two types: lead-acid batteries, which are traditional and require more maintenance, and lithium-ion batteries, which last longer, charge faster, and need less upkeep. The choice depends on the specific needs of your operation!

Understanding Electric Forklift Batteries

Electric forklift batteries are designed to provide the necessary power to operate forklifts, which are commonly used in warehouses, distribution centers, and manufacturing facilities. These batteries convert electrical energy into mechanical energy, allowing forklifts to lift, move, and transport heavy loads effectively.

Wholesale lithium golf cart batteries with 10-year life? Check here.

Types of Electric Forklift Batteries

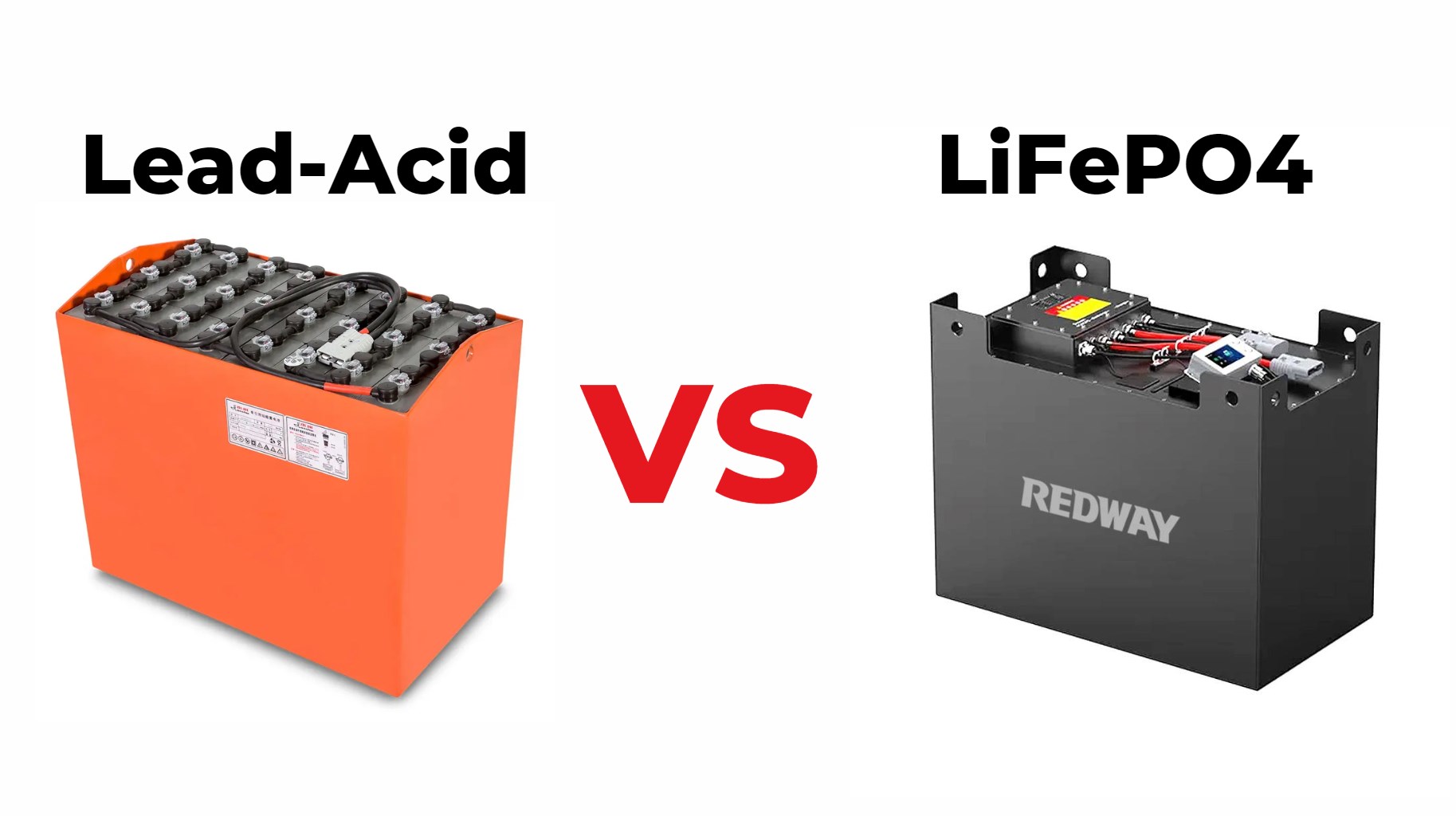

- Lead-Acid Batteries: The most traditional type, lead-acid batteries are widely used in electric forklifts due to their affordability and established technology. They consist of lead dioxide and sponge lead plates submerged in an electrolyte solution of sulfuric acid. While lead-acid batteries are robust, they require regular maintenance and have a shorter lifespan compared to newer technologies.

- Lithium LiFePO4 Batteries: As an advanced alternative, Lithium LiFePO4 batteries are gaining popularity in the forklift market. These batteries provide higher energy density, longer cycle life, and reduced maintenance requirements. They are less prone to sulfation, which is a common issue with lead-acid batteries, leading to greater efficiency and reliability.

Components of Electric Forklift Batteries

- Cells: Each electric forklift battery consists of multiple cells connected in series to achieve the desired voltage. For instance, a typical forklift battery may have a configuration of 24, 36, or 48 volts.

- Battery Management System (BMS): A crucial component of Lithium LiFePO4 batteries, the BMS monitors and manages the battery’s performance, ensuring optimal charging and discharging while preventing overcharging and overheating.

- Enclosure: The battery’s outer casing is designed to protect internal components from physical damage, environmental factors, and chemical spills. Durable materials ensure the longevity of the battery, especially in rugged industrial environments.

Benefits of Electric Forklift Batteries

- Efficiency and Performance: Electric forklift batteries provide consistent power delivery, enhancing the performance of forklifts during operation. Lithium LiFePO4 batteries, in particular, offer rapid charging capabilities, allowing for quick turnarounds during shifts.

- Longer Lifespan: Lithium LiFePO4 batteries can last significantly longer than lead-acid batteries, often providing over 3,000 cycles compared to 1,500 cycles for traditional lead-acid options. This extended lifespan translates to lower replacement costs over time.

- Reduced Maintenance: Unlike lead-acid batteries, which require regular maintenance such as watering and equalization, Lithium batteries need minimal upkeep. This reduction in maintenance not only saves time but also reduces labor costs.

- Environmental Benefits: Electric forklift batteries, particularly Lithium types, are more environmentally friendly. They are recyclable and generate less waste compared to traditional lead-acid batteries, which contribute to pollution during disposal.

Applications of Electric Forklift Batteries

- Warehousing and Distribution: Electric forklifts powered by efficient batteries are essential for moving goods within large warehouses. Their ability to navigate tight spaces while carrying substantial loads makes them invaluable in these environments.

- Manufacturing: In manufacturing settings, electric forklift batteries enable the seamless transport of raw materials and finished products along production lines, enhancing overall operational efficiency.

- Retail and Inventory Management: Retail environments utilize electric forklifts to manage stock levels, facilitating quick inventory turnover and optimal space utilization in storage areas.

- Recycling and Waste Management: In recycling facilities, electric forklifts equipped with reliable batteries assist in the collection and movement of recyclable materials, improving efficiency and productivity.

Selecting the Right Electric Forklift Battery

Choosing the appropriate electric forklift battery involves several key considerations:

- Power Requirements: Assess the power needs of your specific application. Higher voltage batteries (e.g., 48 volts) may be necessary for heavy-duty operations, while lower voltage (e.g., 24 volts) may suffice for lighter tasks.

- Battery Type: Consider whether lead-acid or Lithium LiFePO4 batteries are more suitable for your operations. While Lithium batteries offer greater efficiency and lifespan, lead-acid may be more budget-friendly upfront.

- Operating Environment: Evaluate the conditions in which the forklift will operate. If the environment is prone to spills or chemical exposure, robust battery enclosures and maintenance requirements will be crucial.

- Cost Analysis: Conduct a thorough cost analysis, taking into account initial investment, maintenance costs, and battery lifespan to determine the most cost-effective solution for your business.

Want OEM lithium forklift batteries at wholesale prices? Check here.

Conclusion

Electric forklift batteries are vital for efficient material handling in various industries. With options ranging from traditional lead-acid batteries to advanced Lithium LiFePO4 solutions, businesses can choose the best power source to meet their operational needs. At Redway Battery, we specialize in manufacturing high-quality Lithium LiFePO4 batteries tailored for electric forklifts, ensuring optimal performance and reliability. For custom solutions and quick quotes, contact us today.

Latest News

- Electric forklift batteries primarily come in lead-acid or lithium-ion types, each offering distinct advantages based on operational needs.

- Recent studies emphasize the growing preference for lithium-ion batteries due to their lower maintenance requirements and longer lifespan.

- Industry trends indicate a shift towards more sustainable battery technologies as companies aim to reduce their carbon footprints.

Redway Expert Comment

Electric forklift batteries are pivotal in modern material handling operations. While lead-acid batteries have been the traditional choice, lithium-ion variants are gaining traction due to their efficiency and reduced maintenance needs. As businesses increasingly prioritize sustainability, the transition towards advanced battery technologies will likely continue to accelerate.”