Forklift battery cells are individual electrochemical units that store and release electrical energy through chemical reactions. These cells combine to form a battery pack, powering forklifts by converting stored chemical energy into usable electrical current.

What Are Forklift Battery Cells and Why Are They Important?

Forklift battery cells are the basic units making up a forklift battery, responsible for energy storage and delivery. They are crucial because the performance and lifespan of the entire battery depend on each cell’s health and efficiency.

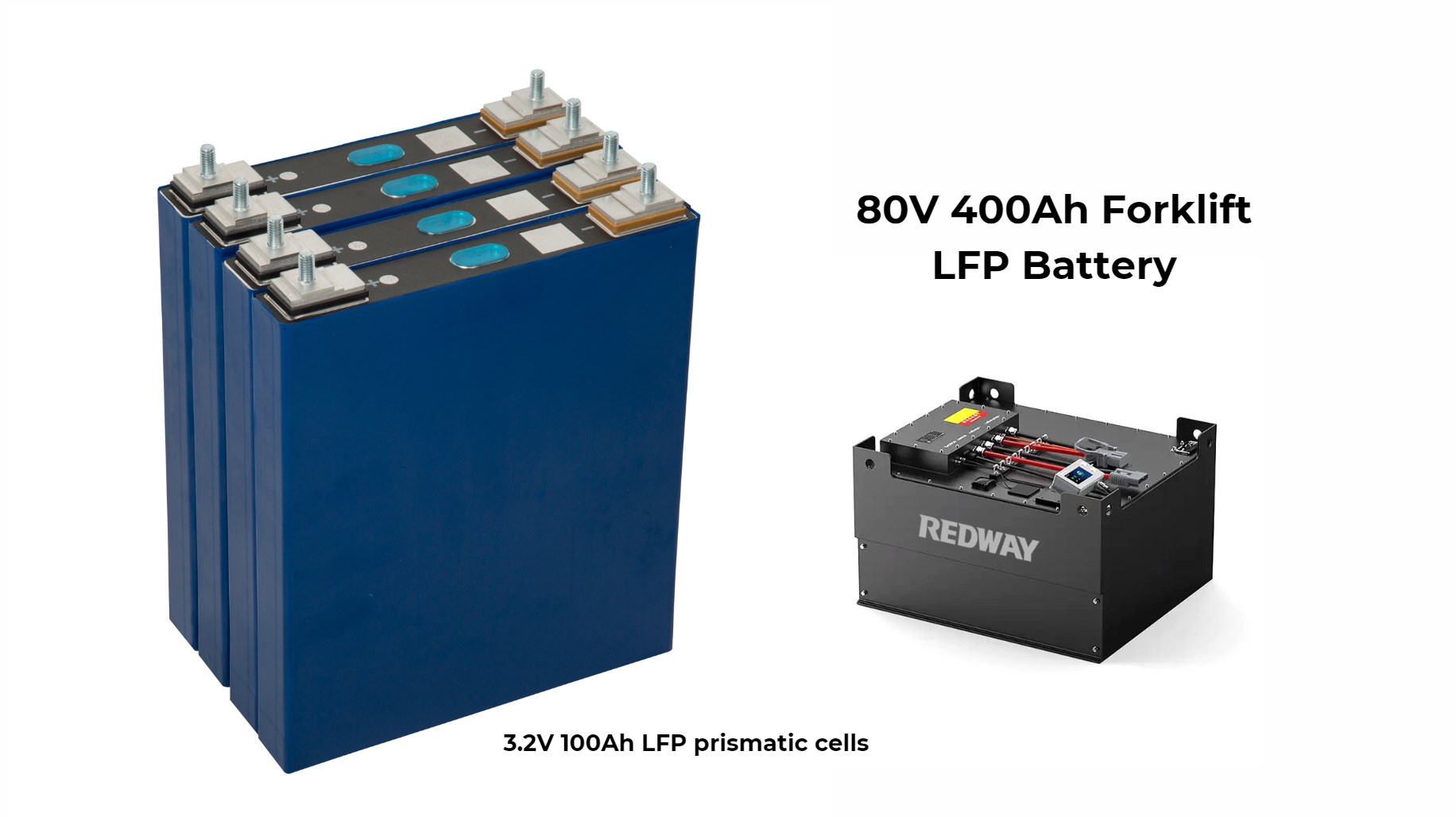

Each cell contains electrodes and an electrolyte that facilitate chemical reactions generating electric current. In lead-acid batteries, cells are connected in series, usually six cells of approximately 2 volts each, to make a 12V battery. Lithium battery cells, such as LiFePO4 from Redway Battery, work similarly but use lithium-ion chemistry, offering higher energy density, greater cycle life, and faster charging capabilities essential for efficient forklift operations.

Wholesale lithium golf cart batteries with 10-year life? Check here.

How Do Forklift Battery Cells Generate and Provide Power?

Battery cells generate power through electrochemical reactions that move electrons from the anode to the cathode, creating an electric current usable by the forklift.

Inside each cell, chemicals interact causing a flow of electrons externally through terminals. During discharge, oxidation at the anode releases electrons which pass through the forklift’s electrical circuit to the cathode where reduction occurs. Charging reverses these reactions, restoring the chemical potential. The collective output of multiple cells in series or parallel determines the forklift’s voltage and capacity. Redway Battery’s engineering ensures optimized cell design and balancing for consistent power delivery.

Want OEM lithium forklift batteries at wholesale prices? Check here.

Which Types of Forklift Battery Cells Are Most Common?

Lead-acid and lithium-ion (especially LiFePO4) cells are the most common types used in forklift batteries today.

Lead-acid cells have been industry standard due to low cost and reliability. Each lead-acid cell produces about 2 volts. Lithium-ion LiFePO4 cells, pioneered by companies like Redway Battery, are increasingly preferred for their lighter weight, higher efficiency, longer cycle life, and environmental benefits. Lithium cells contain better thermal stability and require less maintenance, making them ideal for modern forklift fleets.

| Battery Cell Type | Voltage per Cell | Advantages | Typical Use Case |

|---|---|---|---|

| Lead-Acid | ~2 volts | Low initial cost | Traditional forklifts |

| LiFePO4 Lithium | ~3.2–3.3 volts | Long life, fast charging | High-performance forklifts |

Why Is Cell Balancing Critical in Forklift Battery Packs?

Cell balancing ensures all cells have equal voltage and charge, preventing premature battery failure and improving overall pack efficiency.

Unbalanced cells cause weaker cells to degrade faster, reducing battery capacity and potentially damaging the pack. Balancing is achieved via passive (bleeding excess charge) or active methods and is often managed by a Battery Management System (BMS). Redway Battery’s LiFePO4 packs integrate advanced BMS with automated cell balancing to maximize safety, longevity, and performance in demanding forklift environments.

How Can I Identify and Troubleshoot Faulty Forklift Battery Cells?

Symptoms of faulty cells include reduced runtime, slow charging, uneven voltage readings, and physical signs such as swelling or corrosion.

Testing involves measuring individual cell voltage, conducting load tests, and checking electrolyte specific gravity (lead-acid only). Cells with significantly lower voltage or capacity often indicate sulfation, internal shorts, or irreversible damage. Early identification allows reconditioning or replacement of the affected cells, improving battery reliability. Redway Battery offers advanced diagnostic tools and after-sales support to assist clients in maintaining cell health.

When Should Forklift Battery Cells Be Replaced or Reconditioned?

Cells should be reconditioned or replaced when their capacity drops below 80%, voltage imbalance persists, or when physical damage is evident.

Reconditioning methods like equalization charging or desulfation can sometimes restore lead-acid cells. Lithium cells typically rely on BMS for health management but damaged cells require replacement. Over-reliance on faulty cells leads to diminished forklift performance and potential safety risks. Redway Battery’s engineered cells facilitate easier maintenance, offering options for cell-level repair or full pack replacement.

Where Does Redway Battery Fit into Forklift Battery Cell Innovation?

Redway Battery pioneers OEM lithium cell manufacturing with custom LiFePO4 packs designed for robust forklift applications, combining industrial-grade reliability with cutting-edge technology.

With over 13 years of experience, Redway integrates automated production, MES systems, and ISO-certified quality controls ensuring consistent cell performance. Their engineering team supports tailored cell configurations and BMS integration to optimize power, safety, and longevity, assisting forklift operators worldwide in minimizing downtime and maintenance overhead.

| Feature | Redway LiFePO4 Cells | Traditional Lead-Acid Cells |

|---|---|---|

| Cycle Life | 2000+ cycles | 500-1000 cycles |

| Charge Time | 2-3 hours | 8-12 hours |

| Maintenance Requirement | Low | High |

| Weight | Lightweight | Heavy |

| Safety | High thermal/chemical stability | Risk of acid leaks and sulfation |

Does the Chemistry of Forklift Battery Cells Affect Safety and Performance?

Yes, the chemical composition of the cells directly impacts battery safety, energy density, charge cycles, and thermal management.

Lead-acid cells can emit corrosive gases and require frequent maintenance, posing safety risks if mishandled. In contrast, lithium-ion LiFePO4 cells used by Redway Battery are inherently safer due to stable chemistry, minimal gas emission, and robust design against thermal runaway. Proper chemistry choice improves forklift efficiency, decreases downtime, and enhances operator safety.

Redway Expert Views

“Understanding the internals of forklift battery cells is key to unlocking better forklift performance and reliability. At Redway Battery, we focus on engineering lithium battery cells that balance high energy output with safety and long service life. Our OEM experience allows us to customize battery cells to meet specific operational demands of forklift fleets worldwide, ensuring clients benefit from cutting-edge technology and seamless integration. Continuous innovation in cell chemistry and production processes allows Redway to deliver battery packs that power industries efficiently and sustainably.”

— Redway Battery Engineering Director

Summary and Key Takeaways

Forklift battery cells are foundational components that convert chemical energy into electrical power, directly affecting battery output, lifespan, and safety. Understanding types—primarily lead-acid and lithium-ion LiFePO4—and their working principles helps operators make informed choices for their forklift energy needs. Cell balancing and health monitoring are essential to avoid premature failures, while early identification of faulty cells ensures continued safe operation. Advanced solutions like Redway Battery’s custom lithium cells offer superior performance, durability, and low maintenance, driving forklift productivity and reducing lifecycle cost.

FAQs

Q1: How many cells make up a typical forklift battery?

Typically, lead-acid forklift batteries contain six cells in series; lithium packs vary based on voltage but follow modular designs.

Q2: Can faulty cells cause complete battery failure?

Yes, one bad cell can degrade overall battery capacity and may cause safety issues.

Q3: How does Redway Battery’s LiFePO4 cell design improve forklift operation?

They provide longer cycle life, enhanced safety, fast charging, and reduced maintenance requirements.

Q4: What is cell balancing and why is it necessary?

Cell balancing equalizes charge among cells to optimize pack performance and prevent damage.

Q5: Are lithium battery cells more expensive than lead-acid?

Initially yes, but their longer lifespan and efficiency lead to a lower total cost of ownership.