Lithium batteries connected in parallel can face several challenges, primarily due to issues with consistency, current imbalances, and battery management systems (BMS). These problems can lead to reduced performance, safety hazards, and potential battery failure.

Why is Consistency Important When Connecting Lithium Batteries in Parallel?

When connecting lithium batteries in parallel, consistency among the batteries is crucial. If the batteries have different voltages, capacities, or internal resistances, they will not charge or discharge evenly. This inconsistency can lead to one battery doing most of the work, which may cause it to overheat or fail prematurely. Ideally, batteries should have a voltage difference of less than 10mV, an internal resistance difference of less than 5mΩ, and a capacity difference not exceeding 20mAh to ensure balanced performance.Chart: Recommended Specifications for Battery Consistency

| Specification | Recommended Value |

|---|---|

| Voltage Difference | ≤ 10mV |

| Internal Resistance | ≤ 5mΩ |

| Capacity Difference | ≤ 20mAh |

How Do Current Imbalances Affect Parallel Battery Performance?

Current imbalances occur when batteries connected in parallel experience unequal loads. For example, if two batteries are rated equally but one has a slightly lower capacity or higher internal resistance, it will draw less current than its counterpart. This situation can lead to faster depletion of the stronger battery while the weaker one remains charged longer. Over time, this divergence can result in significant differences in state of charge (SOC), leading to potential damage.Chart: Impact of Current Imbalance on Battery Life

Wholesale lithium golf cart batteries with 10-year life? Check here.

| Current Imbalance (%) | Expected Battery Life Reduction (%) |

|---|---|

| 5% | 10% |

| 10% | 20% |

| 15% | 30% |

What Are the Risks of Nuisance Tripping in Battery Management Systems?

Battery management systems (BMS) are designed to protect lithium batteries from overcurrent and overheating. However, when multiple batteries are connected in parallel without proper design considerations, nuisance tripping can occur. This happens when the BMS mistakenly detects unsafe operating conditions and disconnects the battery from the load or charger. Such disconnections can interrupt power supply and lead to system failures.

How Can Battery Management Systems Mitigate Issues in Parallel Connections?

Advanced BMS can help mitigate issues associated with parallel connections by monitoring voltage, current, and temperature across all connected batteries. They can balance loads more effectively and provide alerts for any discrepancies. Some systems allow for more than two batteries to be connected by implementing tighter tolerances and history functions that report faults and operations.

Want OEM lithium forklift batteries at wholesale prices? Check here.

What Solutions Exist for Safely Connecting Lithium Batteries in Parallel?

To safely connect lithium batteries in parallel, several solutions can be implemented:

- Diode OR Circuits: These prevent reverse current flow between batteries while allowing them to share loads.

- DC-DC Converters: These devices regulate voltage and current distribution among the batteries, helping to equalize SOC.

- Fuses: Adding fuses can protect individual batteries from overcurrent situations but may disrupt parallel configurations.

Chart: Solutions for Safe Parallel Connections

| Solution | Description | Pros | Cons |

|---|---|---|---|

| Diode OR Circuit | Prevents reverse current flow | Simple implementation | Poor current sharing |

| DC-DC Converters | Regulates voltage/current distribution | Better load balancing | Additional cost |

| Fuses | Protects against overcurrent | Simple protection | Disrupts parallel state |

Why Should Different Brands or Capacities Be Avoided in Parallel Configurations?

Using different brands or capacities when connecting lithium batteries in parallel is discouraged due to potential mismatches in performance characteristics. Variations can lead to uneven charging and discharging cycles, increasing the risk of battery failure. It is best practice to use identical batteries from the same manufacturer with matching specifications.

Industrial News

Recent advancements in lithium battery technology emphasize the importance of proper configuration when connecting multiple units in parallel. Companies are increasingly focusing on developing smart BMS that can handle complex scenarios involving multiple battery packs while ensuring safety and efficiency. Innovations such as integrated DC-DC converters within battery designs are gaining traction as they help manage load balancing more effectively.

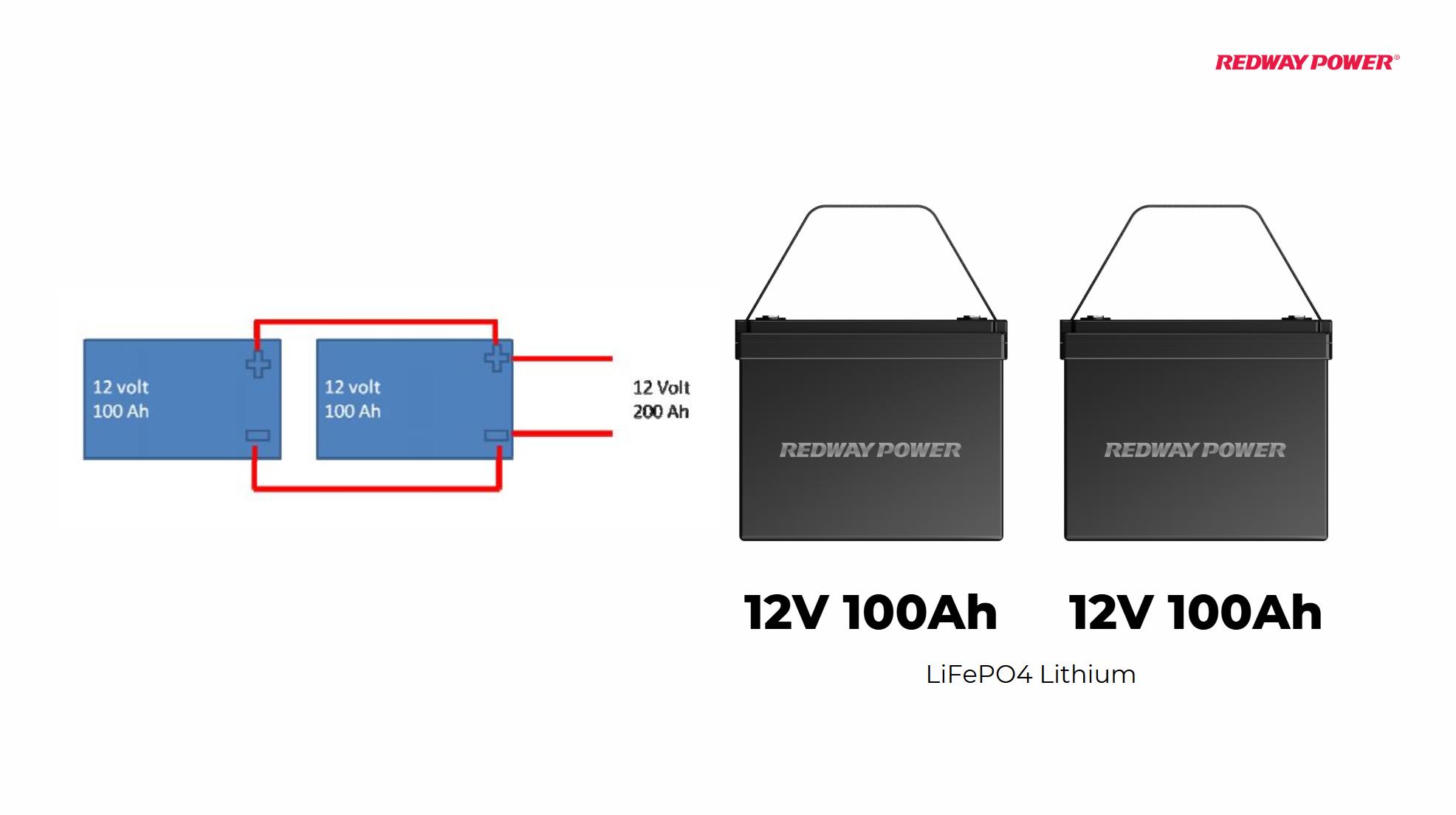

Parallel Connection 101W Large LiFePO4 Batteries

Redway Expert Views

“Properly managing lithium battery connections is vital for longevity and safety,” states an industry expert at Redway Technologies. “As we move towards more complex energy storage solutions, understanding how to mitigate risks associated with parallel configurations will be key to maximizing performance.”

Frequently Asked Questions

- Can I connect different brands of lithium batteries in parallel?

A: It is not recommended as differences in specifications may lead to uneven charging and discharging. - What happens if one battery fails in a parallel configuration?

A: The remaining batteries may take on the additional load, potentially leading to their failure as well. - How often should I check the state of charge for batteries connected in parallel?

A: Regular checks are essential; ideally after every charging cycle to ensure balanced SOC across all units.